I'd suggest not making a shoulder on the drawbar inside the chuck body. Instead, add a shoulder (see also below) to the far end of the drawbar, where it exits the spindle. If nothing else, you'll have a larger diameter for the needle bearing. You might even want to fabricate a drawbar centering collar to fit inside the far end of the spindle, with a nice large flange at its outer end for the needle bearing.

Finally, instead of machining the "shoulder" as part of the drawbar, you could fabricate it as a separate collar, which you can secure to the drawbar with a pin AFTER you have all the parts built and test-ssembled. That way, it can be located in an ideal place to allow tightening the collet.

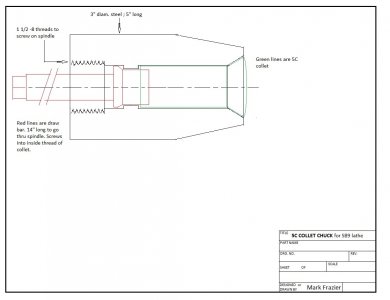

I had actually thought about the draw bar tightening against the rear of the spindle much the same as the 3C collet setup. After looking at it , I believe you are correct and that is the right way to go, But the hand wheel to tighten will have to thread on the .750" draw bar as the draw bar has to go through the spindle and the end of the draw bar in the chuck is 1" in diameter which is too large to go through the spindle.

Spindle bore = just over .750"

draw bar inside chuck to screw into collet = 1"