I spent next to no money on a rototiller that the tines would not stay engaged on. I thought it was a simple fix, but not so much. Turns out that the gear that engaged the tines had about a quarter of it's teeth cracked off!

Long story short, the manufacturer no longer make that gear. (it is specific in that it has an integral cog for a chain). So, I ordered a similar one that didn't have the cog

. These gears are kinda hard, so I had to anneal them.

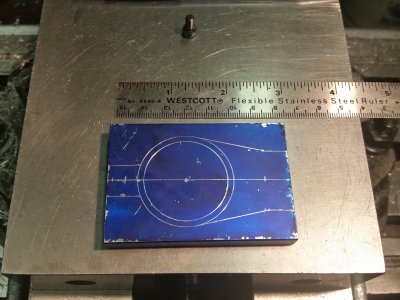

A few days later, I got back to it. I bored out and chamfered all the un-needed stuff from the new gear

. Next, I did the same thing with the old gear

. Next, I set them on a few plates to maintain the reference faces and welded them together

. I annealed it once again, and in a few days, I will try my hand at hardenening. Hopefully this works, otherwise, I'll have to find another rototiller.