-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2014 POTD Thread Archive

- Thread starter Smudgemo

- Start date

- Joined

- Jul 26, 2013

- Messages

- 584

Thank you David,

I really enjoy the hand work and have gained a great deal of appreciation for the craftsmanship of the men who manufactured wooden planes. The accuracy is astounding... !!! Sure, they had jigs, etc. but still... If you look at some of the "boxing" in molding planes, you will see what I mean.

OOps... sorry about the fuzzy pic... how does one delete a pic ?

Any gaps that you see are a result of the planes age, glue dried out and warping.

Brian

I really enjoy the hand work and have gained a great deal of appreciation for the craftsmanship of the men who manufactured wooden planes. The accuracy is astounding... !!! Sure, they had jigs, etc. but still... If you look at some of the "boxing" in molding planes, you will see what I mean.

OOps... sorry about the fuzzy pic... how does one delete a pic ?

Any gaps that you see are a result of the planes age, glue dried out and warping.

Brian

Last edited:

- Joined

- Feb 1, 2014

- Messages

- 339

Replaced a dozen watch batteries today. My wife handed me a bag of dead watches last week, and I finally got everything together to do it. There were pressed on backs, threaded backs and backs that had screws.... Had to get 5 different types of batteries... I am now a watch battery changing expert...

Sent from my iPad using Tapatalk

Sent from my iPad using Tapatalk

- Joined

- Sep 24, 2014

- Messages

- 929

I did 2 watch batteries today and resized my ladies metal watch bracelet

1

1

Replaced a dozen watch batteries today. My wife handed me a bag of dead watches last week, and I finally got everything together to do it. There were pressed on backs, threaded backs and backs that had screws.... Had to get 5 different types of batteries... I am now a watch battery changing expert...

Sent from my iPad using Tapatalk

- Joined

- Feb 1, 2014

- Messages

- 339

I did 2 watch batteries today and resized my ladies metal watch bracelet

1

Oh yeah, that reminds me... I added a link to one of my watches and took one out of one of hers too...

I ended up getting one of those $13 watch tool kits... Spent about $25 for batteries... Not bad for a dozen watches.

Sent from my iPad using Tapatalk

- Joined

- Feb 17, 2013

- Messages

- 4,406

I recently bought a used Gaertner microscope equipped with a measuring reticle. Unfortunately, there was no indication of any scale.

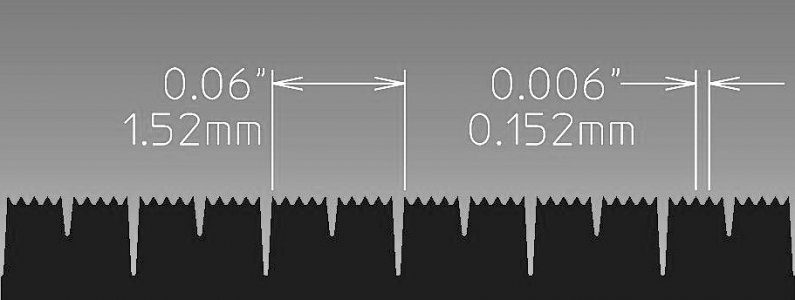

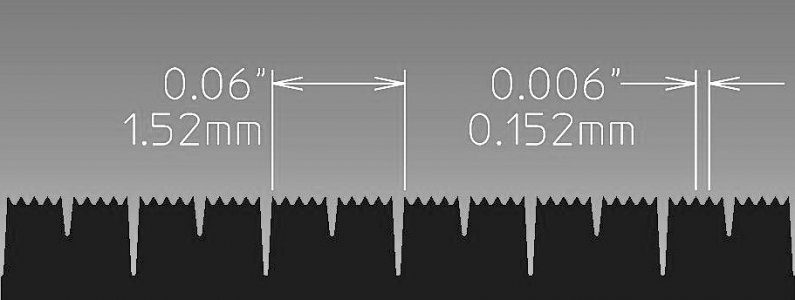

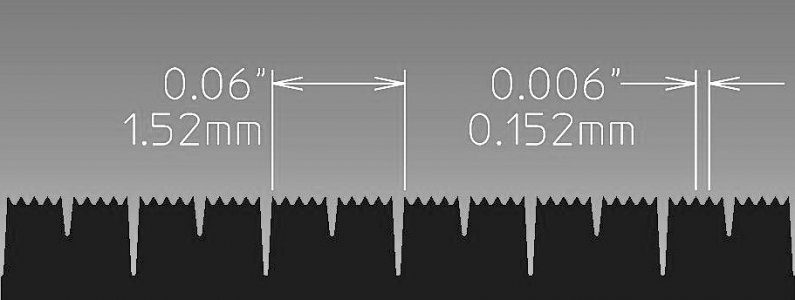

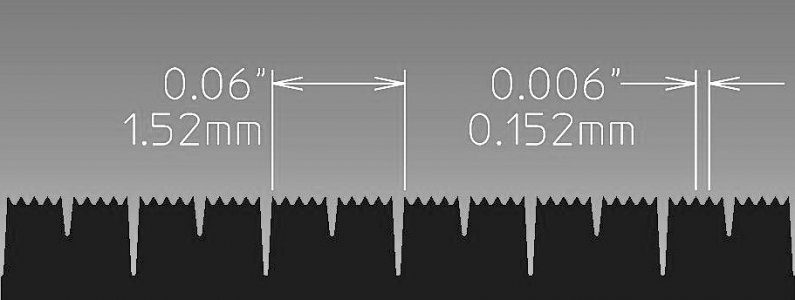

I calibrated the scale by looking at a couple of good quality metric and English (both fractional and decimal) scales I own. The bottom line is that each “tick” of the knob moves the reticle 0.00006”. There’s a sawtooth visible in the field of view that’s used to keep track of full turns. I drew up a representation of it on my CAD and have attched it to the front of the base for general reference.

Next up was illumination. I started by gutting a <FREE> Harbor Freight LED flashlight. Glued the LED assembly to a wooden block angled at 15 degrees. Magnets buried in the V section attach the light to the stand behind the scope tube. I mounted the original battery holder into a wooden surround, added a Masonite retainer, and glued this into the scope base.

A 1/8” audio plug and socket connect power to the lights. No need for a switch - just unplug.

Now I can really look at the working edges of lathe and mill tooling and check my grinding technique. I can also measure some pretty small distances. Not bad for $80, plus the cost of the connectors!

I calibrated the scale by looking at a couple of good quality metric and English (both fractional and decimal) scales I own. The bottom line is that each “tick” of the knob moves the reticle 0.00006”. There’s a sawtooth visible in the field of view that’s used to keep track of full turns. I drew up a representation of it on my CAD and have attched it to the front of the base for general reference.

Next up was illumination. I started by gutting a <FREE> Harbor Freight LED flashlight. Glued the LED assembly to a wooden block angled at 15 degrees. Magnets buried in the V section attach the light to the stand behind the scope tube. I mounted the original battery holder into a wooden surround, added a Masonite retainer, and glued this into the scope base.

A 1/8” audio plug and socket connect power to the lights. No need for a switch - just unplug.

Now I can really look at the working edges of lathe and mill tooling and check my grinding technique. I can also measure some pretty small distances. Not bad for $80, plus the cost of the connectors!

- Joined

- Feb 1, 2014

- Messages

- 339

I recently bought a used Gaertner microscope equipped with a measuring reticle. Unfortunately, there was no indication of any scale.

I calibrated the scale by looking at a couple of good quality metric and English (both fractional and decimal) scales I own. The bottom line is that each “tick” of the knob moves the reticle 0.00006”. There’s a sawtooth visible in the field of view that’s used to keep track of full turns. I drew up a representation of it on my CAD and have attched it to the front of the base for general reference.

View attachment 87391View attachment 87392

Next up was illumination. I started by gutting a <FREE> Harbor Freight LED flashlight. Glued the LED assembly to a wooden block angled at 15 degrees. Magnets buried in the V section attach the light to the stand behind the scope tube. I mounted the original battery holder into a wooden surround, added a Masonite retainer, and glued this into the scope base.

View attachment 87393View attachment 87394View attachment 87395

A 1/8” audio plug and socket connect power to the lights. No need for a switch - just unplug.

View attachment 87396View attachment 87397

Now I can really look at the working edges of lathe and mill tooling and check my grinding technique. I can also measure some pretty small distances. Not bad for $80, plus the cost of the connectors!

That's pretty cool.

Sent from my iPad using Tapatalk

I recently bought a used Gaertner microscope

Next up was illumination. I started by gutting a <FREE> Harbor Freight LED flashlight.

A 1/8” audio plug and socket connect power to the lights. No need for a switch - just unplug.

Now I can really look at the working edges of lathe and mill tooling and check my grinding technique.

That's an innovative way to provide light for the scope. My Gaertner scope has small red and green lamps projecting down at an angle from opposite sides of the scope as well as a mirror reflecting light up from underneath. The red and green seemed like an odd way to illuminate things, but it makes the two sides of elevations on parts stand out much better. The down side of my scope is that the magnification is so great that the depth of field is very shallow. I wish I had gotten some different lenses with the scope.

- Joined

- Aug 22, 2012

- Messages

- 4,115

The down side of my scope is that the magnification is so great that the depth of field is very shallow. I wish I had gotten some different lenses with the scope.

What it the dia of the eyepiece barrel? 0.9? inches (forgotten the exact size) was a common size for microscopes and cheap-store astronomical telescopes.

The telescopes are usually useless so are often thrown or given away. Might be worth a try to find some for experiment.

- Joined

- Apr 23, 2011

- Messages

- 2,476

Brian, if you go to edit your post and click manage attachments the option to select and remove a pic comes up... how does one delete a pic ?

cheers Phil