This is how I installed the Countershaft drive:

Had some leftover decking 1x6 planks (short cut offs)....and build a little bridge to go under the cabinet. Used a floor jack and lifted the assembly and balanced it on the jack. Had my daughter assist by slowly rolling the floor jack inside the cabinet and lifted the counter shaft assembly upward. Pressed it against the underside of the top to keep it stable, and then installed the 2 1/2" carriage bolts. Lowered the jack and sat the motor on the lift and bolted the motor to the mounting plate. That whole assembly is heavy, and the floor jack saved my back!

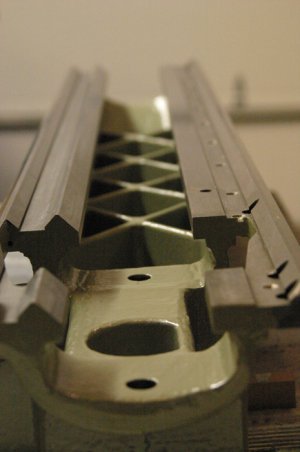

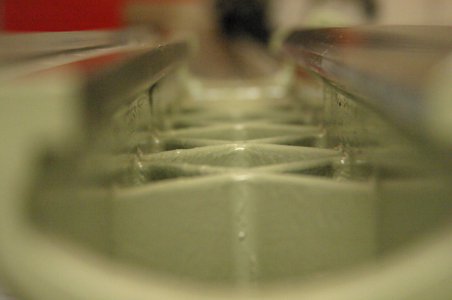

I also installed a thicker 3/8" steel plate on top of the cabinet and under the drip pan. I milled out the belt opening at a friends house with all the proper bolt locations too. Now this baby's got some good support with no sag!

Had some leftover decking 1x6 planks (short cut offs)....and build a little bridge to go under the cabinet. Used a floor jack and lifted the assembly and balanced it on the jack. Had my daughter assist by slowly rolling the floor jack inside the cabinet and lifted the counter shaft assembly upward. Pressed it against the underside of the top to keep it stable, and then installed the 2 1/2" carriage bolts. Lowered the jack and sat the motor on the lift and bolted the motor to the mounting plate. That whole assembly is heavy, and the floor jack saved my back!

I also installed a thicker 3/8" steel plate on top of the cabinet and under the drip pan. I milled out the belt opening at a friends house with all the proper bolt locations too. Now this baby's got some good support with no sag!