I acquired this little Toolroom lathe bad in mid-August. Always wanted a metal lathe and this SB 10L seemed like a stout machine in a small footprint....exactly what I needed.

I have been working periodically on the lathe and learning from all the great SB threads (past and present) on this forum. It is so fun to look at what others are doing and a great learning experience. My goal is to get this complete by Christmas - it will be my present!

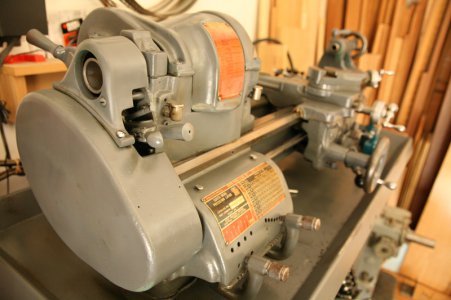

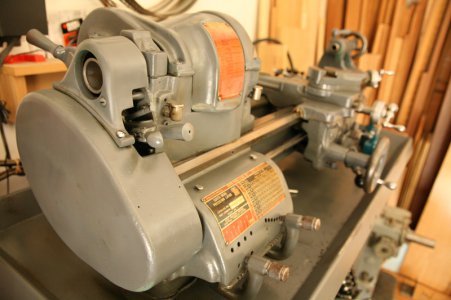

Here is the machine as purchased 3 months ago. Dealer put a spray coat of dark gray over the machine before selling. I really didn't intend to buy and restore the machine, but bearings don't last 47 years....gears need cleaning....parts need repairing....wicks get caked up, etc. You guys know -- it was time. Here is the machine as purchased with the photo show to follow

I have been working periodically on the lathe and learning from all the great SB threads (past and present) on this forum. It is so fun to look at what others are doing and a great learning experience. My goal is to get this complete by Christmas - it will be my present!

Here is the machine as purchased 3 months ago. Dealer put a spray coat of dark gray over the machine before selling. I really didn't intend to buy and restore the machine, but bearings don't last 47 years....gears need cleaning....parts need repairing....wicks get caked up, etc. You guys know -- it was time. Here is the machine as purchased with the photo show to follow