Due to some health-related issues I had to put this lathe project on hold for several months, but I'm slowly getting back to working on it.

My last post shows the lathe up against the wall where I plan on keeping it & I was thinking I would not need to move it from there.

Well, that plan kind of took a U-turn!

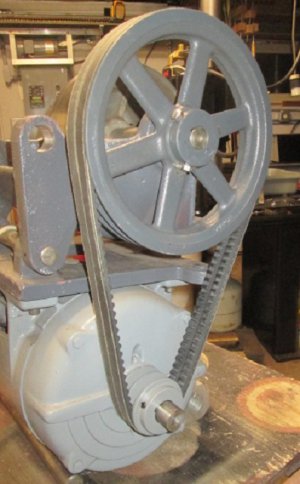

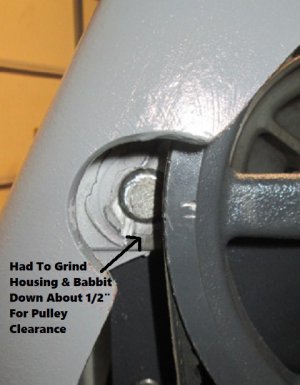

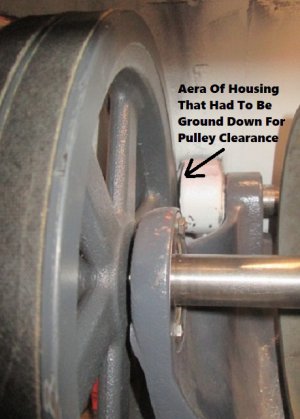

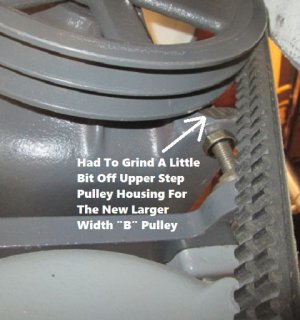

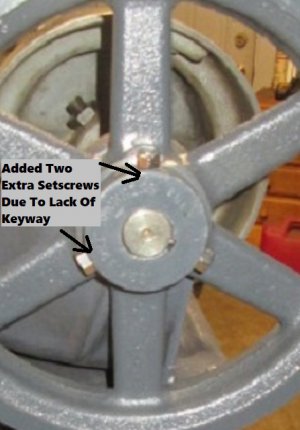

Back when I placed it up against the wall, I didn't have the correct size pulleys & not having the large pulley that goes on the counter shaft I never gave it a thought about installing it.

As it turns out that pulley will not clear the top of the cabinet opening enough to fit on the shaft without removing the motor or lowering the whole assembly down off of the pivot shaft.

To make things more interesting I just placed this

Powermatic 1200HD I recently picked-up & my 20" Walker Turner drill press in front of the lathe! This gives me a roughly three-foot-wide area in-between the lathe & the drill presses which is enough room to use the machines, but not enough to get my shop-crane in there.

This led me to come up with a "Plan-B" option.

I braced some scrap aluminum blocks in-between the bed & the chip pan then I used a small scissor-jack to lift up the bed just enough to get the base out. Once I got the base out, I attached a ratchet-strap to a rafter just as a back-up for the scissor-jack.

With the base clear of the lathe, I was able to use a heavy-duty appliance dolly to move the base around the Powermatic where I have the room needed to work on the base. I basically reversed the previous process of installing the motor & drive assembly.

I just ordered the motor pulley & belts I'll need, so I'm going to wait until I get them installed before reassembling the drive assembly in the base.

Doug