I bought a 13" South Bend turret lathe a little while back & I'm in the process of restoring it.

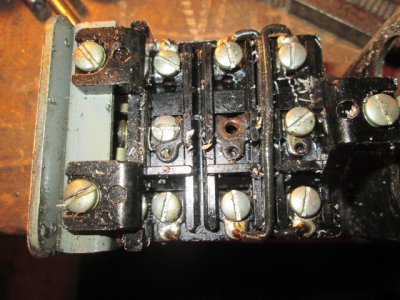

Currently it's all disassembled & the majority of the smaller manageable sized parts I moved into my basement so I can work on cleaning them up & rebuilding them.

I took the base / bed / chip-tray / & a few other larger parts to a local shop that does sandblasting to get the 60 years of caked-on grease & coolant off.

I had a couple days of somewhat warmer weather here in Michigan, so I was able to get a quick coat of primmer on the parts so hopefully they won't start to rust before the weather starts to warm up here a little.

Doug

Currently it's all disassembled & the majority of the smaller manageable sized parts I moved into my basement so I can work on cleaning them up & rebuilding them.

I took the base / bed / chip-tray / & a few other larger parts to a local shop that does sandblasting to get the 60 years of caked-on grease & coolant off.

I had a couple days of somewhat warmer weather here in Michigan, so I was able to get a quick coat of primmer on the parts so hopefully they won't start to rust before the weather starts to warm up here a little.

Doug