- Joined

- Jun 20, 2016

- Messages

- 346

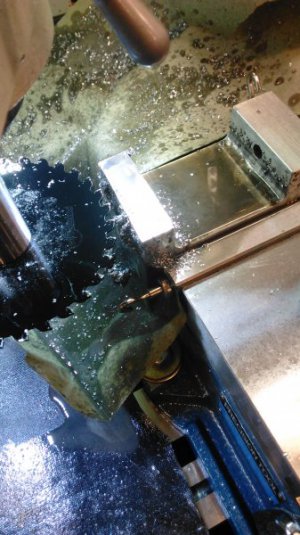

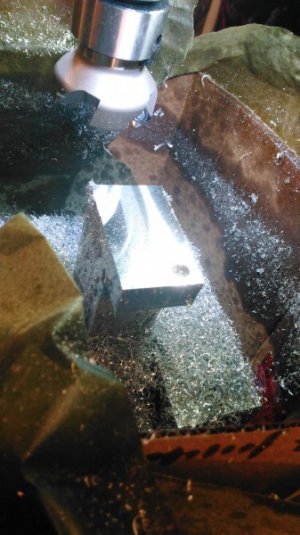

Not immensely complicated but i'm making a V block . I had to hold a round part that I felt was a little too big for my small V blocks so i'm making one . This was a big hunk of 6061 I-beam . I have no clue what it was for, got it in the scrap yard . Been steadily comping away with it . Some slitting saw , face mill , fly cutter . Was getting a weird pattern lastnight with the fly cutter so I reset my nod , tile and everything ...bad idea when it's late and your tired ...I spent 30 minutes chasing my tail checking the L/R head tilt when I realized i was doing it wrong ...lol

--------------------------------------------------------------------------

This rough layout is kind of what i'm shooting for .

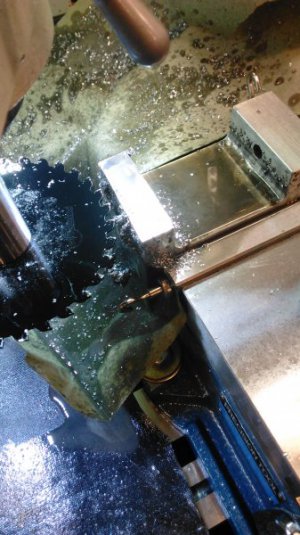

Cutting the long I-beam ends off

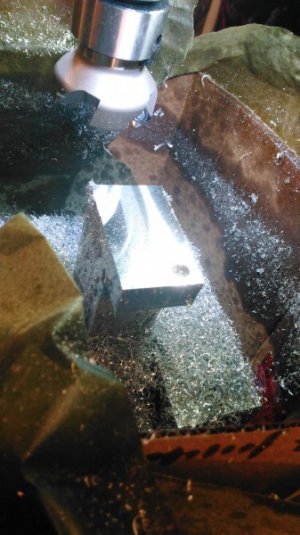

Facing the sides one at a time .

This is where im at . Guess i'll see how accurate i've done. Gotta face 2 more sides then I put it in the vise the angle block under it .

--------------------------------------------------------------------------

This rough layout is kind of what i'm shooting for .

Cutting the long I-beam ends off

Facing the sides one at a time .

This is where im at . Guess i'll see how accurate i've done. Gotta face 2 more sides then I put it in the vise the angle block under it .