- Joined

- Jan 20, 2016

- Messages

- 174

I have asked some questions during my recent rebuild (thanks Rich for your help), and am now almost finished the effort. Posting my rebuild of a 28-300 / 28-380 / 28-390 bandsaw. Different documents show the enclosed base version of the 28-300 basic saw as 28-380 and 28-390, so not sure which one it is. Saw is marked 28-300, but that is without a base. Maybe someone on here will understand the difference in model numbers?

I bought this gal back in May at a local on-line only auction for $60. The only description said something like “never been under power – no info”, with 3 poor quality photos. Could see the metal cutting gear reduction shaft was there (no pulley) so knew it was the metal/wood version, and could see the upper blade guide was MIA. As I had just finished a major rust repair to the deck of the Gravely and was extremely tired of cutting 1/8 sheet metal with jig saw and grinding discs, I decided to take a chance on it.

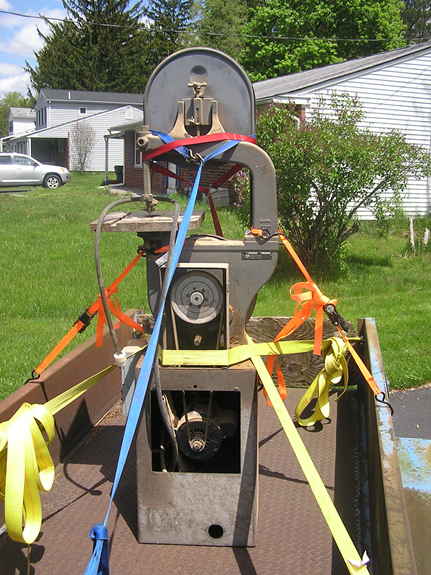

Here she is before I unloaded it in the driveway. Let’s just say she was rode hard and put away wet frequently. PO must not have been very mechanical, as could see lots of things jerry rigged and or messed up after scraping away worst of the crud.

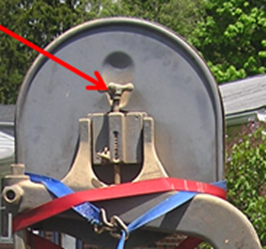

Hate this tension adjusting knob in center of rear door, my fat fingers make it hard to turn there. Will raise it up above the door during the rebuild.

At first exam, this 1974 model 28-380 was missing the upper blade guide and guard, both 4 step pulleys were missing, the blade tension adjuster rod and nut were both stripped, the high/low speed clutch was frozen, the motor was 3450 rpm and not working (hums), missing lots of little things and hadn't even gotten into it yet. Checking some prices for used parts on the web and this $60 purchase was starting to look like it needed $700 in parts, which is what a decent one sells for locally. Basically made it look like a parts machine! After receiving some coaching on here, including lots of VERY helpful information locating manuals and p/l, I decided to try to resurrect it, as at least I would know exactly what I had when I was done (and I can't go anywhere anyway, so needed something to do).

Spent better part of last 8-10 weeks researching, tearing down, cleaning, and figuring out how it was supposed to work. Then buying LOTS of parts, repairing everything, all new bearings/seals, filing the burrs off of every casting and sharp edge, making a fair amount of missing/buggered up parts, painting (even tried to match the original 2 tone paint job) and reassembling it. A new HF 1800 rpm 1 hp motor, new switch and wiring, some more head scratching, and she is now proudly back among the living.

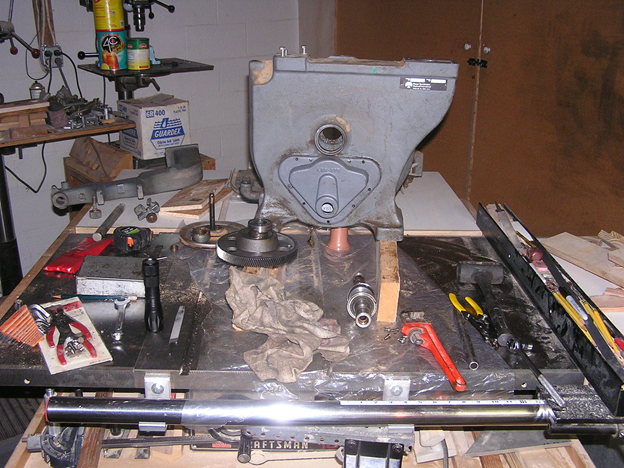

First the tear down. It only takes about an hour or two to turn the bandsaw into piles up rubble.

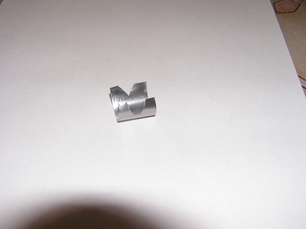

Started with the simple repairs while waiting for all the ordered parts. The upper wheel mounts to this stud, and it pivots on a shaft in the hole to allow for blade track adjustment. The housing hole was .021 looser than the pin, so after a bit of head scratching, decided to cheap out and make this .010 shim. Was able to get the pin back in pretty snug. First upgrade finished.

First batch of cleaned and straightened dark machine gray painted parts, then the stone gray upper/lower doors (closest to garage door, can barely see the 2nd upper door sideways behind first one).

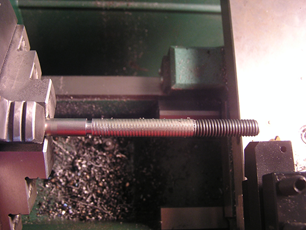

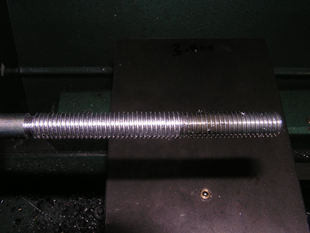

One of next things fixed was the stripped tension rod and nut. I did not like turning this knob in back in middle of the door, so bought a 3/8-16 x 13” long McMaster grade 8 bolt to raise it above the upper door like the newer models. Set the bolt up in the lathe, made the threading undercut, picked up the old threads, then cut the new ones to 4.5 inches long. Turned it around and turned the hex head off so old knob could be pinned onto new bolt.

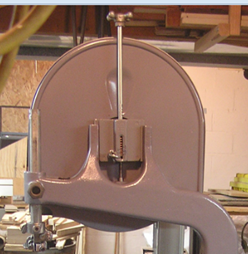

Put it back together with the old knob on new longer bolt above the upper door. Was way better than before, but still took too many turns to go from loose to tight (8 turns?).

Decided to take the knob off and made a handle for it from piece of 1/2 x 1 x 5 scrap, a rusty shoulder screw, and then made a new rotating handle for it out of UHMW. Could have bought a $67 plastic handle from McMaster, but no fun in that. Much nicer now! Takes a few seconds to adjust, not minutes.

Hard to see, but the end of the old tension screw just pushed right against the casting. I drilled a 1/4 hole, then turned a 1/2 ID bowl shaped holder for a pair of $5 Amazon flat thrust bearings. Now the end of the screw pushes against the trust bearing, so the tension handle turns very easy, even under load.

One can buy the standard $30 Danly yellow die spring to replace the crushed worn out original spring, or buy the $18 ebay one, or can buy the $9 green Raymond equivalent on McMaster. This was the gold one I ried first, but have the green one in there and works better. No picture of it, but I made a new nut out of )1 tool steel that was 1/2" thick. Heat treated it and installed it. Another good upgrade.

I bought this gal back in May at a local on-line only auction for $60. The only description said something like “never been under power – no info”, with 3 poor quality photos. Could see the metal cutting gear reduction shaft was there (no pulley) so knew it was the metal/wood version, and could see the upper blade guide was MIA. As I had just finished a major rust repair to the deck of the Gravely and was extremely tired of cutting 1/8 sheet metal with jig saw and grinding discs, I decided to take a chance on it.

Here she is before I unloaded it in the driveway. Let’s just say she was rode hard and put away wet frequently. PO must not have been very mechanical, as could see lots of things jerry rigged and or messed up after scraping away worst of the crud.

Hate this tension adjusting knob in center of rear door, my fat fingers make it hard to turn there. Will raise it up above the door during the rebuild.

At first exam, this 1974 model 28-380 was missing the upper blade guide and guard, both 4 step pulleys were missing, the blade tension adjuster rod and nut were both stripped, the high/low speed clutch was frozen, the motor was 3450 rpm and not working (hums), missing lots of little things and hadn't even gotten into it yet. Checking some prices for used parts on the web and this $60 purchase was starting to look like it needed $700 in parts, which is what a decent one sells for locally. Basically made it look like a parts machine! After receiving some coaching on here, including lots of VERY helpful information locating manuals and p/l, I decided to try to resurrect it, as at least I would know exactly what I had when I was done (and I can't go anywhere anyway, so needed something to do).

Spent better part of last 8-10 weeks researching, tearing down, cleaning, and figuring out how it was supposed to work. Then buying LOTS of parts, repairing everything, all new bearings/seals, filing the burrs off of every casting and sharp edge, making a fair amount of missing/buggered up parts, painting (even tried to match the original 2 tone paint job) and reassembling it. A new HF 1800 rpm 1 hp motor, new switch and wiring, some more head scratching, and she is now proudly back among the living.

First the tear down. It only takes about an hour or two to turn the bandsaw into piles up rubble.

Started with the simple repairs while waiting for all the ordered parts. The upper wheel mounts to this stud, and it pivots on a shaft in the hole to allow for blade track adjustment. The housing hole was .021 looser than the pin, so after a bit of head scratching, decided to cheap out and make this .010 shim. Was able to get the pin back in pretty snug. First upgrade finished.

First batch of cleaned and straightened dark machine gray painted parts, then the stone gray upper/lower doors (closest to garage door, can barely see the 2nd upper door sideways behind first one).

One of next things fixed was the stripped tension rod and nut. I did not like turning this knob in back in middle of the door, so bought a 3/8-16 x 13” long McMaster grade 8 bolt to raise it above the upper door like the newer models. Set the bolt up in the lathe, made the threading undercut, picked up the old threads, then cut the new ones to 4.5 inches long. Turned it around and turned the hex head off so old knob could be pinned onto new bolt.

Put it back together with the old knob on new longer bolt above the upper door. Was way better than before, but still took too many turns to go from loose to tight (8 turns?).

Decided to take the knob off and made a handle for it from piece of 1/2 x 1 x 5 scrap, a rusty shoulder screw, and then made a new rotating handle for it out of UHMW. Could have bought a $67 plastic handle from McMaster, but no fun in that. Much nicer now! Takes a few seconds to adjust, not minutes.

Hard to see, but the end of the old tension screw just pushed right against the casting. I drilled a 1/4 hole, then turned a 1/2 ID bowl shaped holder for a pair of $5 Amazon flat thrust bearings. Now the end of the screw pushes against the trust bearing, so the tension handle turns very easy, even under load.

One can buy the standard $30 Danly yellow die spring to replace the crushed worn out original spring, or buy the $18 ebay one, or can buy the $9 green Raymond equivalent on McMaster. This was the gold one I ried first, but have the green one in there and works better. No picture of it, but I made a new nut out of )1 tool steel that was 1/2" thick. Heat treated it and installed it. Another good upgrade.