Hi

@aliva

I do not disagree with your vision. I too normally just guess, with some experience, until I find a feed that cuts nice for the current work material. However,

@davidpbest provides, in his book, some nice rules about what the feed rate "should be" for a given tool insert and its physical dimensions. That would help a lot with the inital "guess". Read on and you will see why...

However, the our two lathes PM1340GT and PM1440GT we found that the Power Feed rate to Cross Feed rate is NOT 1:2 as the lathe plate and the manual says. And this maybe of value to someone out there. I have also studied the gearing diagrams for the 1440 at length and found it to be in error. When I look at similar older models manuals they are wrong also. So I suspect that it is something that just propagates.

So I wanted to learn more about programing Excel spread sheets with macros which is to say is programing via Visual Basic for Applications, VBA. As a vehicle to learn this I have been trying to write programs which both help me to learn as well as might be useful to someone. My first attempt at this was to write some G-code in a spread sheet and then to use the Macros code to generate a lathe front electronic panel for my VFD conversion. The program allows one to make a round hole, with Keyways and/or flats on it of any size, orientation, and location. You can make as many of these or any variation and place them in space. In addition it does rectangular holes as well as Sub-D connector holes of the most common sizes. Mix and match. Obviously you can also make holes for other applications using the same program. After you describe the number of holes and their other attributes of sizes, locations, orientations, flats etc. then the program automatically will generate the Gcode to make such a panel or other multi-hole device. One can also add other shapes to the program. If you have not seen it,

HERE is the thread for the VFD conversion which employees this control front panel for my lathe. And,

HERE is the thread for the Excel Gcode generator.

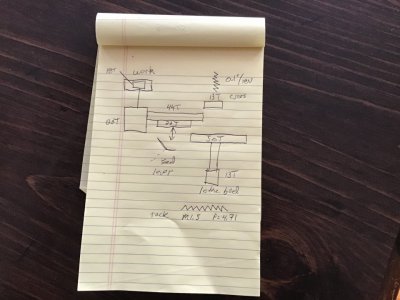

Having finished that to some degree I wanted to continue with my education. So I have been working on an Excel spread sheet which will calculate all of the TPI values that one can obtain with a set of gears for a given lathe. It also provides the TPI values that one would get if he were to use the Power Feed rather than the lead screw and 1/2 Nut. Yes, I know there are reasons one might not want to do this, but when one is desperate he might use it and if so one would like to know the Feed rates to better than one or at most two digits. I have found that what is on the front of the lathes is not very exact! In doing so I decide to list the X-feed rates as well and I did not want to put out something that was wrong. So away I went. The exercise has also allowed

@Ischgl99 and I , and hopefully now, others to develop an understand what is inside the apron gear box for these two lathes.

So far my tool calculates the correct TPI for any set of external gears that one might have as well as all of the standard thread sizes. It generates a large table of TPI values (and all other associated distances etc). This can then be searched or just printed as a table for reference. I did these calculations for these two lathes using the external gears that come with them plus a 35T for the 1340. For the simpler 1340GT there are 5122/2 TPI values using the split nut and the same number using the feed bar. A minor fraction of these are redundant, but I will let the user deal with that. The 1440GT has a different and more complex gear box and so it has 6144 using the split nut and 1536 using the Feed bar. I have a program that will search this list and find all of the TPI values around a value of your choice.

Now I am trying to make the spread sheet as user friendly as I would want it to be. After that I will post it for everyone to have and if someone wants to add another lathe that would be great. I might even do it for them if I know what it is and how its gears etc are configured.

I do not know what lathe you have, but would you be interested in getting a table, spread sheet, etc. ? With or without exact feed rates!

Dave L.