-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

When delicate stuff has to be done with something HEAVY ?

- Thread starter graham-xrf

- Start date

- Joined

- Feb 25, 2021

- Messages

- 3,271

I'm following along with interest, in part because I have a 5' cast straight edge, and good sized surface grinder that I'll eventually want to true up. My new shop will include a 1 ton bridge crane and 12' ceiling, so the overhead structure will be there, but the challenges of dealing with a heavy straight edge still requires something similar to what you're contemplating.

I do have a 3' x 4' granite plate. I plan to have a 10' x 12' office/metrology room with better temperature stability to keep it in, but that will have a 8' ceiling, so printing large things on the granite plate also has some constraints. Quite likely a unistrut solution will be used there.

I appreciate the aversion to chains, as they can both damage things and just get to be clumsy.

I'm not sure where my electronics bench is going to end up, similar equipment

I do have a 3' x 4' granite plate. I plan to have a 10' x 12' office/metrology room with better temperature stability to keep it in, but that will have a 8' ceiling, so printing large things on the granite plate also has some constraints. Quite likely a unistrut solution will be used there.

I appreciate the aversion to chains, as they can both damage things and just get to be clumsy.

I'm not sure where my electronics bench is going to end up, similar equipment

First off, forklift battery maybe wrong term.Klein makes about 5 models, but the 268 you are referring to is just one component, the block. Even for the best fit for your description, I cannot imagine how you rigged it. I'd have to see a photo to understand who you are using it.

-- I used to be a technical rope rescue instructor, so I understand pulley systems quite well (as well as my engineering and rigging background).

All this to say that you have come up with something really special! I would love to see how you rigged it, even with a dummy load!

Batteries FOR the forklift better.

The original battery was toast, sold it to some poor scrap guy from out of town, dropped in his 1 /2 ton Chevy with all the rest of his stuff and the bumper about hit the ground.

We made a battery box same size to hold what we can find.

Still have contacts with cell site vendors and got some 170 Amp hr batteries, these weigh in at 120 or so pounds.

4 inches wide, 22 long and 13 tall.

VRLA and can stand on end so strap around the battery and the block and racke anchored to the cage over the top a d it is up and in.

They fit perfectly with about 1 inch clearance front back and 6 units wide about 7 inches.

Sent from my SM-G781V using Tapatalk

- Joined

- May 27, 2016

- Messages

- 3,479

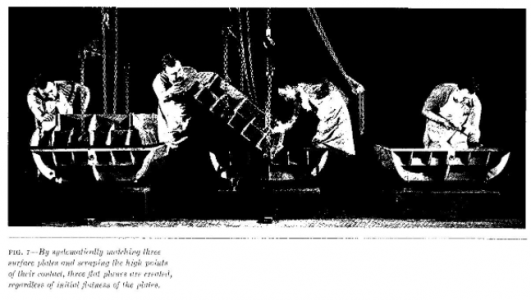

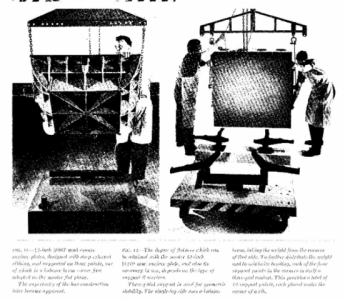

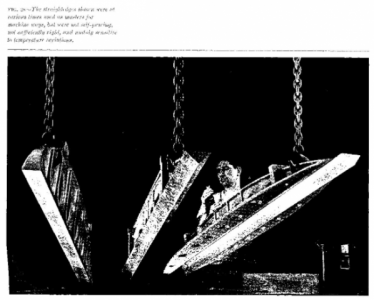

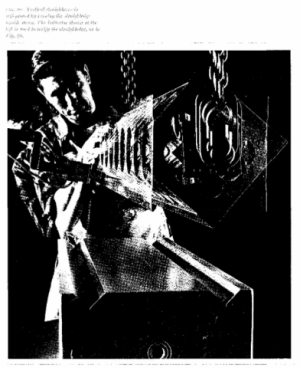

Thanks so much for the pictures. "Foundations of Mechanical Accuracy" is one I do have. Like Connelly, it's not one that most folk would read from end to end. We choose the bits we need instead.If you haven't read it yet, there are some great examples of exactly what you want to do in Foundations of Mechanical Accuracy. Screen shotted a few for fun reference. Great book BTW.

View attachment 387804

etc ..

The images depict their solutions for a variety of situations, likely found more or less in the same way we have been discussing here. As always, we figure out ways to solutions as we go along, while having dipped into the past to get ideas, and avoid repeating mistakes.

Some of those tools in the pictures are truly mighty!

In my case, the need is to discover the truth of, and help fix up as needed, the ways of 36" lathe beds, with the future possibility of a 48".

It seems that to lift the bed takes near the same or less effort than to lift the straight edge tool. This inevitably leads to the (comedy) thought that I could consider just leaving the straight edge set down on it's three support points, and dangle the lathe bed instead.

So is that a truly dumb notion? (It's OK to laugh ROTFL)! I know that only in this forum could I ask such a question!

@rabler : I have been considering getting a granite 48" on the long dimension, much like yours, though possibly only 30" wide. I would ask how much you love the thing? How useful is it to you? Aside from the very reasonable deal I got on the straight edge, part of my reasoning was the straight edge would do what I needed, and I would only need a bigger granite if ever I I was trying to work on the SE itself.

Re: The 12 x 10 measure room.

8' ceiling is high enough for near everything, provided your hoist can get over most of what you want, which probably includes parts of the floor adjacent the granite. If the joists over it go across the 10' span, and you use (say) 2' centres, then Unistrut(s) hanging off them, fixed along the 12' length right near the walls the whole length, lets you trolley a small RSJ, a bit less than 10' long, that would span the whole room. The load, plus the self-weight of the beam, is shared between two Unistruts, anchored right near the walls, the Unistruts themselves supported every 2'. I think the load limit would be what it takes to un-bend Unistrut rolled over edges. In any event, something like this gives the ability to haul up the load, and move sideways to over the granite, and back, possibly to set down onto a DIY floor trolley.

A thing like a surface grinder bed, or any other part with ways, is going to need the ability to be moved sideways.

The size of the RSJ going across the room depends on the weight of what you might hang in the middle, but being only 10' or so long, I am thinking you could use a relatively small section RSJ, say 3" x 4", or use double-depth Unistrut, or some other thing you might weld together.

You might have to get up to some creative projects to end up with a trolley & hoist system that is economical on the high-value height clear between the granite and the beam. In extremes, you might "shorten the legs of the granite stand", but we hope it never comes to that!

Last edited:

- Joined

- Feb 25, 2021

- Messages

- 3,271

@rabler : I have been considering getting a granite 48" on the long dimension, much like yours, though possibly only 30" wide. I would ask how much you love the thing? How useful is it to you. Aside from the very reasonable deal I got on the straight edge, part of my reasoning was the straight edge would do what I needed, and I would only need a bigger granite if ever I I was trying to work on the SE itself.

Re: The 12 x 10 measure room....

I haven't really had the chance to use the 3'x4' plate. The construction crew is suppose to frame up the new shop next month (January). As you know there is a lot of work that goes into a new building. I've been trenching water, power, internet, gas. Arranging for the electrical upgrade (200A to 400A service). Once the shell of the building is built, I'll need to frame out the measure room, insulate and wire the whole building, put in a ceiling, build the cranes, etc. I'm probably at least a year out from being functional in the new shop.

I do like rebuilding machines for my own use. So issues like this are highly relevant to how I lay out my shop. I may actually go with a small bridge crane in the office. Anything that is big enough to justify using a 3'x4' surface plate is probably bigger than I want to lift repeatedly. And if I do it I'll want at least 1000lbs/ ~450Kg capacity. A 10' span is small enough it wouldn't need a large I-beam (U.S. terminology, RSJ appears to be the UK equivalent), probably a W6x9.

I'll need to get the 3'x4' plate calibrated before I really trust it. I got it recently from an auction, $180 including loading in my truck. I also have a ridiculously large 50x86 granite plate that was a CMM table. That won't go in the temperature controlled room, too big.

I know it's a ridiculous amount of equipment for a hobbyist. Circumstances meant we spent less than half of what we planned on a retirement home, so this is where the extra money is going, along with some simple remodeling projcets. Large agricultural property with no zoning restrictions like you've had to comply with.

Last edited:

- Joined

- Feb 25, 2021

- Messages

- 3,271

I'm leaning toward top running bridge cranes to make the most of the height.You might have to get up to some creative projects to end up with a trolley & hoist system that is economical on the high-value height clear between the granite and the beam. In extremes, you might "shorten the legs of the granite stand", but we hope it never comes to that!

- Joined

- May 27, 2016

- Messages

- 3,479

@rabler

In UK - we also call it I-beam when it has that cross-section.

RSJ => "Rolled Steel Joist", a more general term for most sections. To some extent, we are into culture terminology.

If the I-Beam is horizontal, it's a "joist", and if you stand it vertical, it becomes a "stantion".

$180 bucks, for a 3'x4' granite, I think, is an outrageous steal! We reserve judgement until you find out if it's any good, and if it turns out to be so, the HM guys will probably have some suitable expressions for you and the deal!

Re: Temperature controlled

Of course granite has a temperature coefficient of expansion, but I don't think it's surface changes significantly from flatness, so long as the granite temperature has permeated somewhat to be about the same deep enough, if not all the way through. Putting a (thick) insulated lid cover over, and adding removable insulation side panels around, or use a insulation blanket, could preserve retained heat overnight, when heating isn't on.

Perhaps put a permanent fitted insulation board on the underside. It could well speed up the settle next day.

If it has to do a spell of work requiring what amounts to a temperature controlled environment, and you make the boundaries of that environment an insulated box, a low power little thermostat controlled heater underneath for overnight, may be all you need.

In UK - we also call it I-beam when it has that cross-section.

RSJ => "Rolled Steel Joist", a more general term for most sections. To some extent, we are into culture terminology.

If the I-Beam is horizontal, it's a "joist", and if you stand it vertical, it becomes a "stantion".

$180 bucks, for a 3'x4' granite, I think, is an outrageous steal! We reserve judgement until you find out if it's any good, and if it turns out to be so, the HM guys will probably have some suitable expressions for you and the deal!

Re: Temperature controlled

Of course granite has a temperature coefficient of expansion, but I don't think it's surface changes significantly from flatness, so long as the granite temperature has permeated somewhat to be about the same deep enough, if not all the way through. Putting a (thick) insulated lid cover over, and adding removable insulation side panels around, or use a insulation blanket, could preserve retained heat overnight, when heating isn't on.

Perhaps put a permanent fitted insulation board on the underside. It could well speed up the settle next day.

If it has to do a spell of work requiring what amounts to a temperature controlled environment, and you make the boundaries of that environment an insulated box, a low power little thermostat controlled heater underneath for overnight, may be all you need.

Last edited:

- Joined

- Jul 28, 2017

- Messages

- 2,564

If using a heater you probably want to avoid hot/cold regions on your surface plate. Things like electric blankets have heater strips in them, not a uniform heat source. The resultant thermal gradients will cause height variations. So I don't think this is an approach that will work in a Just Get'er Dun sort of way.

If the surface plate is inside a well-insulated box most of the time it should equilibriate on its own and therefore stay as flat as possible. And keep the electric bill in check

If the surface plate is inside a well-insulated box most of the time it should equilibriate on its own and therefore stay as flat as possible. And keep the electric bill in check

- Joined

- Feb 25, 2021

- Messages

- 3,271

I plan on eventually have a separate mini-split for that room. The plan would be to set the temperature for something reasonable for about 24 hours before any really precision measurements. I'd like to get the plate re-certified to class A, IIRC it was last certified to that in 2016. It'll definitely be a well insulated room, and inside the general building which I'll keep some minimal climate control. I'm going to be spending a lot on insulation for the whole project.

If I'm remembering correctly from the civil engineers, here a "beam" implies horizontal and a "column" is vertical.

Hopefully I haven't completely derailed your thread.

If I'm remembering correctly from the civil engineers, here a "beam" implies horizontal and a "column" is vertical.

Hopefully I haven't completely derailed your thread.