You got it. Chip clearancing can be as aggressive as it needs to be to help chip removal- something especially important with aluminum. With such a fine cut, you don't want to be dragging chips and gumming things up. When you rub soft metal chips under great speeds and pressures between the back of the unclearanced cutting tool and the work, it turns into smeary caca. That is the technical term for it.

Keep in mind, you can take as much metal off to clearance the tool as you want, as long as you preserve the cutting edge and leave enough material to provide adequate strength. I would leave the bottom dished at 1 degree like an end mill for some clean-up action on the base of the cut, but that only needs to include half of the tool diameter to work- the back half of the tool does nothing but support the cutting edge and get in the way of exiting chips. Split the difference between the two to suit the job,

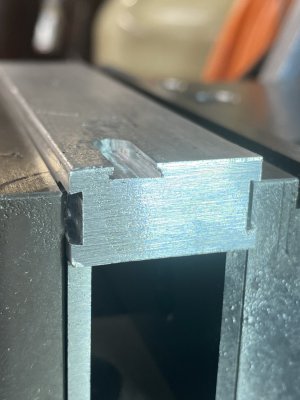

The reason the neck of the dovetail isn't coming out well is that part of the tool isn't clearanced as you did with the base of the tool. The way I make my d-bit clearance cuts is really simple using the dividing workhead on the Sheckel (Shars cloned Deckel). It is going to take a wall of six dollar words without pictures and videos, but I can give it a shot. It might be better than trying video on my phone. I am pretty sure Stefan Goetteswinter covered the technique in his introductory d-bit Deckel video, though. You grind the back side and meet the point. Conceptually it's that simple, but there are some setup tricks to pulling it off with the Sheckel as it's equipped. I kinda pick stuff like this up without much input, so I don't have too bad a time navigating areas that are sparse in documentation. The Deckel manual is the gold standard on this subject. There are several models and manuals over the years, so looking at them all and aggregating the information is helpful. Then Harold Hall covers cutters well beyond the d-bit chapter in his workshop practice book. Some of the good texts that cover d-bits go back 120 years, I like to look up the tool and cutter chapters in any shop manuals I find. Kurt Moltrecht is easy to read, he has a chapter on d-bits too.

I guess the only equipment consideration is the wheel; that small profile might be easier to cut with a sorta cheap 1/16" CBN cutoff wheel. A tool that small can be ground on three edges of the CBN wheel, and its narrow kerf would make grinding the cutter's waist easy. I have a $24 Shars wheel that I double-mount with a flaring wheel (2 wheels, one mount) for those critical gash cuts on the faces of end mills- the ones you can't sharpen the mill without. That's what I'd reach for if I were grinding your d-bit pattern.

Last comment since finish is important (and I'm avoiding feeds and speeds because we all own mills here) is to not just stone the tool, but hone it. Hone it until you cut yourself, then go for the next finer stone. You want to be afraid of that tool when you touch the edges.

Nawww, not the last comment. 50 HRC is just fine, it'll cut right through aluminum. If you want a longer lasting tool you can aim for more hardness, but for a few short, slow cuts there is nothing to worry about.

![20230118_230212[1].jpg 20230118_230212[1].jpg](https://www.hobby-machinist.com/data/attachments/391/391425-768f029428b3986fff8f843eeee1c3cf.jpg?hash=do8ClCizmG)

![20230118_230204[1].jpg 20230118_230204[1].jpg](https://www.hobby-machinist.com/data/attachments/391/391426-a54d0aa27a2c3e7db31c96f8233d108a.jpg?hash=pU0KonosPn)