- Joined

- Mar 26, 2018

- Messages

- 8,759

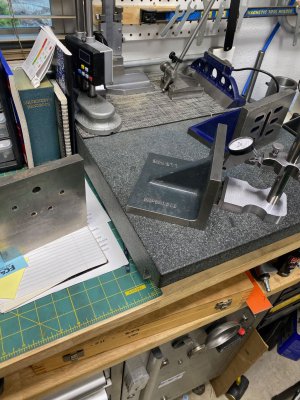

I'm not done yet (heat treat to follow)

I had to try it out. =Rock solid and repeatable.

I tried it out on my scraped sample-known square to two other angle plates I've surface ground.

All three are within .0005" of square!!

I then tried it out on a cheap 2x4x6, out by .006"

Hey, I have a new precision shop tool!!

It only took me 187 hours but look at the money I saved.

but look at the money I saved.

I had to try it out. =Rock solid and repeatable.

I tried it out on my scraped sample-known square to two other angle plates I've surface ground.

All three are within .0005" of square!!

I then tried it out on a cheap 2x4x6, out by .006"

Hey, I have a new precision shop tool!!

It only took me 187 hours