- Joined

- Aug 6, 2015

- Messages

- 4,291

Just documenting the acquisition of my surface grinder. Purchased Nov 29, 2024. The owner was a tool and die maker that passed away and his son is selling everything in the garage.

Not doing much to it, just need to:

Photos when I went to pick it up... brother-in-law went with me to help. I rented a drop deck trailer.

Brother-in-law went with me to help... I should have left him home... he talked reason, common sense and facts and prevented me from grabbing a few more tools... son of a gun...

Once home, more photos to have for future reference

Motor

Anyone knows how to determine the year for this SG?

220V or 440v? 1-phase or 3-phase?? Need to sort that out...

Needs serious cleaning... plus I want to get a new grinding wheel... need suggestions as to what I should get as my first one. Brand and grit size.

Need to validate that the oiler is working

Not doing much to it, just need to:

- Clean, clean, clean... not sure if I will repaint it... thinking about it

- Redo all the wiring since what is in there currently, is in need of replacement

- Validate if it is wired to run it on 240v, if not, rewire to 240

- Replaced dust collector hose

- Validate dust collector is working

- Validate oiler is working, if not, rebuild

- Magnetic vise does not seem to be working correctly... can't seem to be able to release the parts

Photos when I went to pick it up... brother-in-law went with me to help. I rented a drop deck trailer.

Brother-in-law went with me to help... I should have left him home... he talked reason, common sense and facts and prevented me from grabbing a few more tools... son of a gun...

Once home, more photos to have for future reference

Motor

Anyone knows how to determine the year for this SG?

220V or 440v? 1-phase or 3-phase?? Need to sort that out...

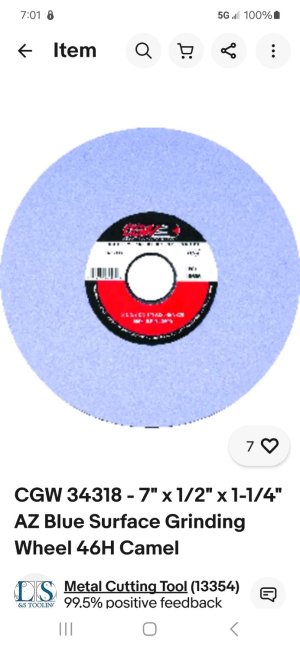

Needs serious cleaning... plus I want to get a new grinding wheel... need suggestions as to what I should get as my first one. Brand and grit size.

Need to validate that the oiler is working