I understand that a three jawed lathe chuck is not ideal to use as a mill holder.

At this point I don't really know enough about milling

To make a educated decision on what I need.

I will be researching this upgrade because I know I have options.

Oh by the way what is a draw bar?

Thanks

The draw bar holds the MT3 taper in place so it can't pull out of place. You don't have to buy it, you have a lathe. Turn a chunk of aluminum to fit in the other end of the spindle and with a step to seat against the spindle end. Run a threaded rod through and into the collet/holder. Use a nut to snug it up. To remove, loosen the nut and tap the end with a hammer, preferably non-marring. It doesn't take a lot of torque, I believe about 40 ft-lb for MT. ER types need almost 100 ft-lb.

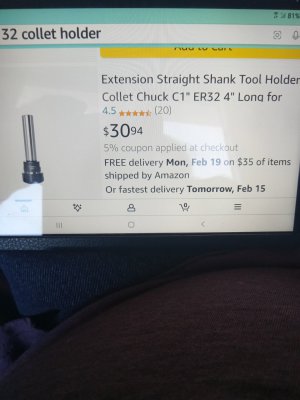

If you were interested in ER collets anyway, they are a good choice. You can get ER holders that adapt to MT3, or that mount in place of your 3-jaw. There are pros and cons to both types.

If you want collets without the adapters, there are MT3 collets around. They might be a good choice for your application, but it would require you to get right up on the spindle as there is not much stick-out with them. It is likely the most rigid setup for this, and would likely have the lowest runout as there are fewer interfaces.

The big pro right now for an MT3 end mill holder is that they are cheap.