Its kind of more complicated with a mill, but the same idea.

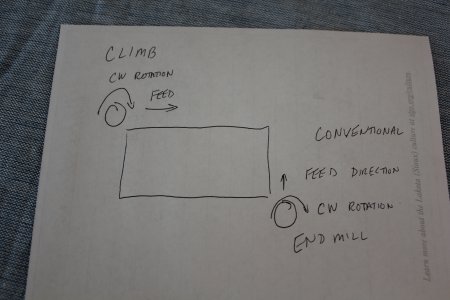

Basically if you imagine the recoil force being put on the part, if it is pushing backwards against the direction of the mill, that is "conventional" milling, basically if there is any backlash, its being taken up by the mill pushing back against the leadscrew

climb milling is the opposite way, if the mill has backlash and the recoil forces exceed the force it takes to move the table, it will cause the endmill to jump forward and drive into the work, a really bad situation, but otherwise if taking very light cuts, it gives a much nicer finish.

// just imagine the endmill being a wheel and your work being the road, if its going against the direction you are going, that is conventional, if it is "helping" the mill along, that is climb

Steve Shannon, P.E.

Steve Shannon, P.E.