- Joined

- Sep 8, 2019

- Messages

- 4,392

Maybe the OP has need of a (micrometer) carriage stop.

Maybe the OP has need of a (micrometer) carriage stop.

Robert, generally I take your word as gospel but I'm not sure about the above. I've got a 0XA QCTP on my Atlas 618 and I have a mixture of 1/4" and 3/8" HSS tooling in Shars toolholders. The 3/8" bits fit perfectly. I don't have any 1/2" tooling but I think it would be adequately secure. More than half the width of the tool bit would be within the body of the tool holder and the set screws would have sufficient 'meat' to clamp down on.although you can apparently fit 3/8" and 1/2" square tooling in the slot, they will not be as stable as either of the two smaller sizes.

Robert, generally I take your word as gospel but I'm not sure about the above. I've got a 0XA QCTP on my Atlas 618 and I have a mixture of 1/4" and 3/8" HSS tooling in Shars toolholders. The 3/8" bits fit perfectly. I don't have any 1/2" tooling but I think it would be adequately secure. More than half the width of the tool bit would be within the body of the tool holder and the set screws would have sufficient 'meat' to clamp down on.

I don't think there is any advantage to using 1/2" tooling but I don't see any significant drawback. Certainly 3/8" tooling has worked well-enough for me. (As has 1/4" tooling.) Am I missing something?

Craig

I have the same lathe and am learning the basics on it. Sounds like you've got a good handle on the chucks and QCTP cutters and such. For this lathe, i'd focus more on HSS tooling/cutters. It's a light duty lathe and relatively slow - not ideal for carbide cutting.

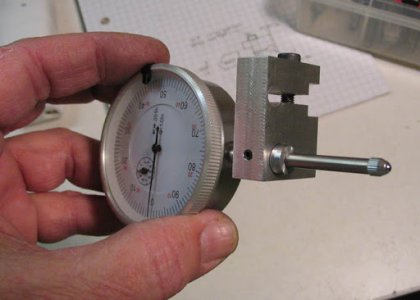

I made a carriage stop that holds a dial indicator. I use it all the time. I keep a 2" indicator in it for most of my work, but sometimes swap it out for a 1". I also have a milling attachment that never gets used. And since they cost about 1/3 or more of what a factory reconditioned benchtop manual Taig milling machine (which works much much better for milling) goes for, they're not worth it in my book. Before i got my little benchtop mill, i found light milling on the drill press with a cross slide vise worked better than the milling attachment on the little lathe.

Other things you'll probably want/need:

magnetic base or two,

dial indicator(s),

a test indicator,

micrometers (i usually use a 0-1" and a 1-2"),

calipers (a 6" ought to cover you),

a machinist's 6" steel ruler,

center drills,

a surface gage,

a bottle of dykem fluid,

a tube of prussian blue (for test fitting / finding high spots),

a decent grinding wheel with a good tool rest to sharpen your HSS tooling,

some honing stones or diamond sharpeners (also for the HSS tooling),

way oil and spindle oil,

some sort of chip tray (i use a small plastic tray from IKEA),

good work lighting,

an acid brush and old paint brush (for sweeping away chips),

a work apron to keep your clothes from getting too messed up),

and, if you don't already have one, a threading dial.

I also find that a set of T-handle allen wrenches is easiest to use for the various lathe adjustments.

Also, regarding collets, i picked up an ER 25 / MT 2 collet chuck and set of collets. If you use the MT 2 collet chuck, you'll need to make or buy a draw bar for it. I made one up using some threaded rod, which is OK. I do plan to make an ER 25 chuck that threads onto my spindle, which will allow long pieces to pass through the head stock.

I'm also making up a clamp for my rotary tool that will mount in my QCTP. Not ideal, but it will allow me to do some light tool post grinding when i need to. I've got a little Proxxon rotary tool with good bearings and a 20mm diameter ring machined on it at the working tip. It should work well enough.

You may or may not find a reversing switch for your motor useful. I've used mine more than once, but it's not necessary.

Have fun with it. I enjoy using mine. I'm learning a lot.

paulh

I have a 12x36 lathe. Here are my most used accessories (nearly all are Shars imports):

Machine Accessories

Measuring tools

- 6" 3 jaw chuck

- 8" 4 jaw chuck

- Live Center

- AXA Toolpost and maybe 15 total holders (don't need many to start)

- 1 lb dead blow hammer

- Little cylinder of lead melted inside copper pipe (1.5-2" Dia x 3" long), great for centering parts in a 4 jaw

- 5/8" keyless drill chuck

Cutting Tools

- Noga style magnetic indicator base

- .001" Dial Drop Indicator 1"

- .0005" Dial Test Indicator (Fowler extended travel, I use this every single day, if I could keep one tool, this would be it)

- .0001" Dial Test Indicator (Interapid, get one when you start thinking of higher precision stuff)

- Thread pitch gauges (cheap and very useful)

- Calipers

- 0-6" Micrometer set

- 6" Steel rule

Misc.

- 115 piece drill set

- Center Drills

- Taps

- Assorted indexable tools 1/2" shank (HSS is perfectly fine if you prefer)

- CCMT RH (most used)

- CCMT LH

- SCMT 45 Deg Chamfer

- VCMT RH

- VCMT LH

- Ext Threading

- 3/8" Boring Bar

- 1/2" Boring Bar (most used)

- 3/4" Boring Bar

- Grooving Tool

- HSS Parting Tool

- Over/Under Reamer set

- Assorted Reamers

- Needle bottles with various cutting fluids

- Bottle of Steel Blue layout fluid

- Copy of Machinery's Handbook, particularly for the threading tables (very useful)

I've gotten a lot of my measuring tools and other accessories / tooling used. I avoid used end mills and carbide cutters, but HSS is so easy to sharpen, used is fine in my book. Helps stretch the dollar.

For the carriage stop, i made one of these:

View attachment 317500View attachment 317501

It works great. The website "Deansphotographica" shows how to make it. http://www.deansphotographica.com/machining/atlas/atlas.html

The South Bend "How to Run a Lathe" book is another time tested standard read, also easily available in hard copy or pdf. South Bend also issued an excellent booklet on grinding/sharpening HSS lathe cutting tools. It's available in pdf here: