-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tramming a vise- the easy way

- Thread starter 682bear

- Start date

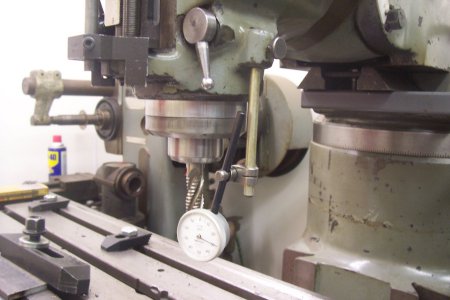

These vise tramming threads always end up providing some unique ideas here and there. So far I haven't found anything being more simple and fast as just clamping an Indicol to the spindle loaded with the .0005" indicator of your choice, and just tap it in. Maybe I'm missing something, but this shouldn't take more than a matter of minutes to accomplish, and with tools that are normally already at hand within reach of the mill.

- Joined

- Jan 28, 2022

- Messages

- 1,730

Good Morning, I have had jobs where I had to remove the vise from the table to use my rotary table and then back to the vise and also clear the table for long work for the same job. Thats why I attached the vise stop to realign the vise on the table. It's true that tramming the vise is not all that time consuming but for me it removes that step. I would like to add something that I do when "0"ing my vise is to use the built in mount provided on my Bridgeport head for bringing in the vise rather then use the spindle as a gauge mount. Thanks for the reply.These vise tramming threads always end up providing some unique ideas here and there. So far I haven't found anything being more simple and fast as just clamping an Indicol to the spindle loaded with the .0005" indicator of your choice, and just tap it in. Maybe I'm missing something, but this shouldn't take more than a matter of minutes to accomplish, and with tools that are normally already at hand within reach of the mill.

Last edited:

Hi Charles, your vise stop is one of the most clever ideas I've seen on a vise tramming thread. I think it's excellent!Good Morning, I have had jobs where I had to remove the vise from the table to use my rotary table and then back to the vise and also clear the table for long work for the same job. Thats why I attached the vise stop to realign the vise on the table. It's true that tramming the vise is not all that time consuming but for me it removes that step. I would like to add something that I do when "0"ing my vise is to use the built in mount provided on my Bridgeport head for bringing in the vise rather then use the spindle as a gauge mount. Thanks for the reply.View attachment 428846

- Joined

- Jan 28, 2022

- Messages

- 1,730

Good morning, I'm glad you like the idea and I'm sure I am not the first to try this. This is why this site is so important and we can all learn something new. When I read posts by others I see how many knowledgable people are sharing opinions and help. Thanks again.Hi Charles, your vise stop is one of the most clever ideas I've seen on a vise tramming thread. I think it's excellent!

- Joined

- Feb 21, 2022

- Messages

- 849

If you have enough height, clamp a key to your rotary table and hold it in the vice.Good Morning, I have had jobs where I had to remove the vise from the table to use my rotary table and then back to the vise and also clear the table for long work for the same job. Thats why I attached the vise stop to realign the vise on the table. It's true that tramming the vise is not all that time consuming but for me it removes that step. I would like to add something that I do when "0"ing my vise is to use the built in mount provided on my Bridgeport head for bringing in the vise rather then use the spindle as a gauge mount. Thanks for the reply.View attachment 428846