today I decided to make the table stops for the work head on my grinder. Those little buggers took me all day. a lot of angles and fitting.

I started with a couple of 3/8" brass bolts. I milled .050" of two of the opposing sides too get the correct width to fit the "t" slot. I then put them in the vise on the mill and used a fly cutter set to the radius of the inside of the "t" slot and cut the back of the bolt head to just fit in the table slot.

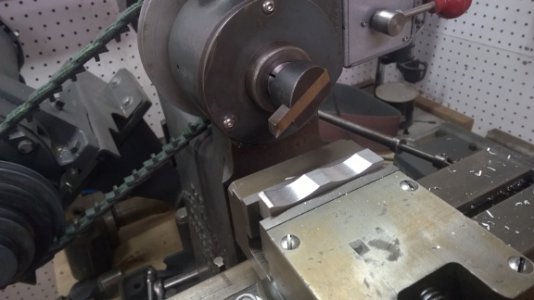

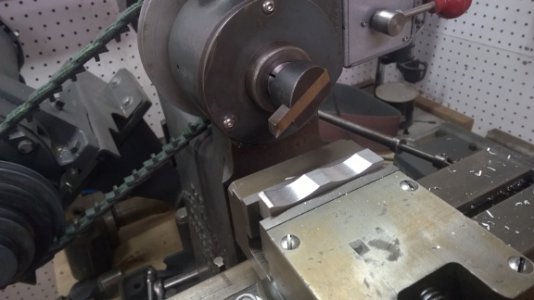

This is the fancy set up to make the bolts fit the curved slot.

Next , I turned the bolts down to .187" and threaded them 10-32. I found they were way off center because I had milled the one side of the head, so I put a .050" shim under that jaw to center the bolt back up for turning.

The top bolt is what I started with and the bottom two are what they end up like.

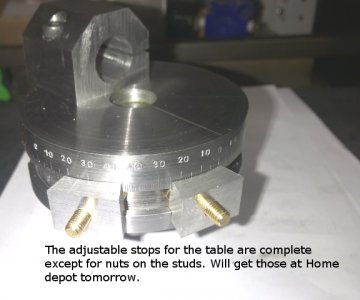

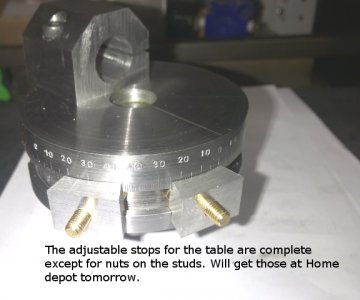

The bolts fit the table slot perfectly.

I set up an aluminum block to make the stop blocks. I set the fly cutter to the radius of the outside of the table and cut two grooves ( one for each block).

Using the same fly cutter, I cut a groove on each side to make the tongue the fits into the slot. I cut one side, turn the block around , pick up the arch and cut the second step on the other side. After these were cut , I cut the block into pieces on the band saw and milled an angle on each end of the block so that the side of the block is square with the radius of the table. ( this was the hard part. I cut and fit, cut and fit until i found the right angle).

I drilled a clearance hole for 10-32 in the center of each block and this is the finished parts.

After 4 hours of work, I have some very nice table stops. I will go to home Depot tomorrow and pick up some pretty knurled brass nuts to hold the blocks in position.