E

ecdez

Forum Guest

Register Today

Re: Code issue, please help. This stopped being fun a few days ago.

OK, max rapid is 250 so I set it at 25 and checked the voltage. Got it pretty much equal in both directions at .510 volts ±.002. Ran my favorite test circle and still have the 6 and 12 o'clock offset although it is decreasing in severity.

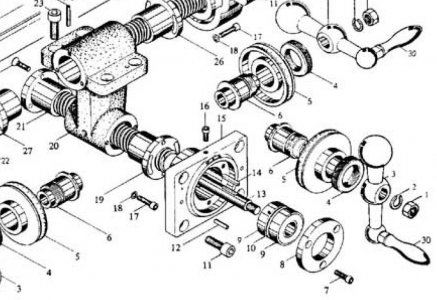

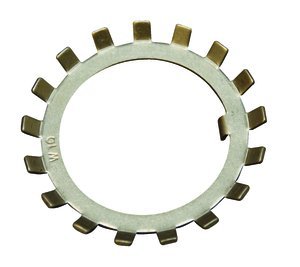

I did notice a slight thud when the Y axis changed directions that the X does not have. I didn't get a chance to write the code for the 2" movement yet to check the accuracy of the movement but now I'm wondering if I also have a backlash problem. I didn't see any thrust bearings on the body of the mill but I'm also not sure exactly what I'm looking at. My small CNC has thrust bearing on the handwheel side of the ballscrew that can be tightened. Are the large CNC's made the same way? That pulley appears to on there pretty good and I don't want to break it just for some exploration.

Anyone have experience with this?

OK, max rapid is 250 so I set it at 25 and checked the voltage. Got it pretty much equal in both directions at .510 volts ±.002. Ran my favorite test circle and still have the 6 and 12 o'clock offset although it is decreasing in severity.

I did notice a slight thud when the Y axis changed directions that the X does not have. I didn't get a chance to write the code for the 2" movement yet to check the accuracy of the movement but now I'm wondering if I also have a backlash problem. I didn't see any thrust bearings on the body of the mill but I'm also not sure exactly what I'm looking at. My small CNC has thrust bearing on the handwheel side of the ballscrew that can be tightened. Are the large CNC's made the same way? That pulley appears to on there pretty good and I don't want to break it just for some exploration.

Anyone have experience with this?