Thankyou so much for your help here really appreciate it ive used that little machine shop calc in the past and did for this job but the noise was just hurendous at the speeds that were shown  .

.

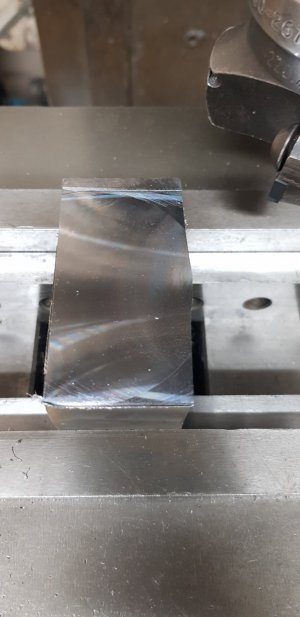

I upped the feed rate and it just sounded even worse and prodced more burs (pictured) im assuming this is bad as it looked more like the material was being pushed rather than cut?

Ill shall have ago at tramming and see if it improves the cuts so thanks for the vid!

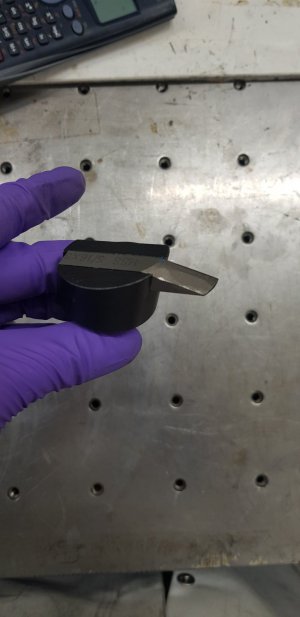

Ive looked around in the tool cabinet for this miller and managed to dig out some bits (pictured) one is i think the fly cutter you spoke of but i think the insert is ground to the wrong shape (plus ive never used one before)

The cutter displayed in the video and then one youve shown earlier (not had chance to shop yet) require inserts?

Thanks for all the help hinestly its nice to get some answers to confusing noises (and scary) ones haha

Edit: just tried with 2 inserts defently better still some noise and a little vibration but with a better finish BUT these are fresh tips....

I upped the feed rate and it just sounded even worse and prodced more burs (pictured) im assuming this is bad as it looked more like the material was being pushed rather than cut?

Ill shall have ago at tramming and see if it improves the cuts so thanks for the vid!

Ive looked around in the tool cabinet for this miller and managed to dig out some bits (pictured) one is i think the fly cutter you spoke of but i think the insert is ground to the wrong shape (plus ive never used one before)

The cutter displayed in the video and then one youve shown earlier (not had chance to shop yet) require inserts?

Thanks for all the help hinestly its nice to get some answers to confusing noises (and scary) ones haha

Edit: just tried with 2 inserts defently better still some noise and a little vibration but with a better finish BUT these are fresh tips....

Attachments

Last edited: