- Joined

- Nov 16, 2012

- Messages

- 5,596

Hi Andy,

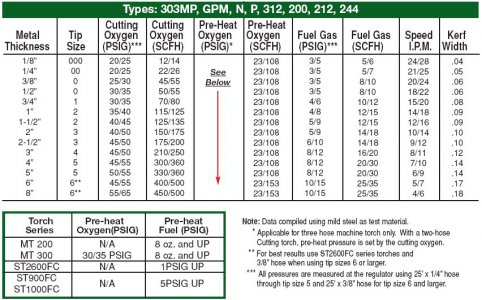

That's a nice chart. Do you happen to have one for propane? I do very little torch cutting and a quick reference for both acy and propane would save me some time.

Thanks

That's a nice chart. Do you happen to have one for propane? I do very little torch cutting and a quick reference for both acy and propane would save me some time.

Thanks

Also be aware victor style tips come in two torch sizes. There's a 1 and a 3. There may be more sizes. Where did size 2 go? I've only seen 1 and 3. I'd hate for you to plunk down money just to find out you can't use the tip in your torch. There's also another size number that specifies the size of the orifices. So you can buy a torch size 1 tip in orifice sizes: 000, 00, 0, 1, 2, 3, etc. I think they refer to the torch size as "series".

Some guys swear you should cut the fuel off first. Other guys swear you should cut off the oxygen first. The manual for my victor torch says cut the oxygen off first. So guess which way I do it. Read and follow the manual that matches your equipment. Easy enough.

The victor tips for acetylene aren't recommended for propane. You might be able to use them. I've never tried. I only use about two tips sizes, so I just bought the tips made to work with propane. These tips have "GPN" in their part number. Again they come in (at least) two sizes, 1 and 3.

Tips will cost you somewhere around $12 each and $15 for the GPN ones. They last me a couple of years so it's not a big expense. If you increase your torch height after you start the cut, you can avoid clogging the tip and they last longer. Also get a set of small drills or "pin files" to clean the holes. Try not to increase the size of the holes when cleaning.

See the attached chart to relate orifice sizes to the thickness of metal you want to cut. You can use a larger tip to cut a particular size of metal. Just be aware the cut may be a little more ragged. This can save you a little money if you don't want to buy several sizes right away. I find I usually put in the #1 tip and go with it. Your steadiness of hand will mean more on a clean cut than the oversized tip.

A 4 lbs hammer is great for smoothing up the end of the cut. It knocks off any slag, but also beats down most of the little ripples. This gives you a consistant fit-up for welding.

View attachment 53022