I finished my first full day in the shop today! That felt so good! Didn’t actually get any machining done - the DRO on the lathe gave up a few days ago so was just prepping that for a new scale. I’ve had a few problems with the glass scales on my machine so I’ve gone for magnetic now. I did that to the cross slide a while back and have been impressed so far. I think it’s coolant that eventually works it’s way onto the glass scale itself. Cleaning it does work as a temporary fix but it’s happened a number of times now which means I don’t fully trust it.

The DRO failure led to a couple of scrapped parts before I noticed the error. No biggie, I ordered a heap of extra material in anticipation of the next 3 batches that I have been promised but still it’s a bit of a pain to have to re make parts! I had a lot of trouble with chip evacuation boring them to size. 28 mm bore 120 mm deep boring from both sides. The finish pass was good with no chatter but the roughing passes were a nightmare with chips getting caught on the back of the boring bar. I’ll maybe need to invest in a 16 mm boring bar next time I’m putting in a tool order. There just isn’t enough clearance for that many chips with a 20 mm bar! Using the through coolant did help a bit but the chips still don’t break up as much as I’d like. Maybe try a higher feed for the roughing pass. Would help or even a second coolant nozzle aimed in the bore. As if one wasn’t messy enough!

Almost bought a CNC lathe too but bailed at the last minute! It was going very cheap so had to fight hard not to buy it but I read online that the controllers have a nasty habit of destroying hard drives and the support for them over here in the U.K. is practically non existent. Sounds like I dodged a bullet there! The search continues! To be fair, I don’t need one yet and I’ve never programmed a machine in my life but I want to learn! The dream is semi automate manufacturing so I can press a button and go home for the night! I know that’s a very simplified view but I have a product I wish to develop which would lend itself very well to this process.

Thinking about it turning a hobby into a business is probably a silly idea. Instead of having a business need for equipment I have a personal desire to own all sorts of machines regardless of whether they will actually bring in any paying work. Still, it beats sitting in an office!

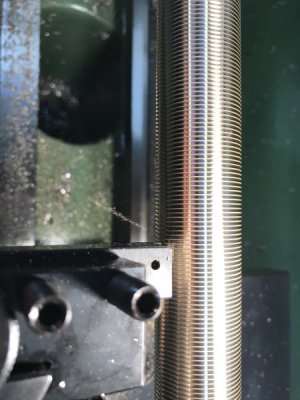

And just to give you guys something more than what should probably kept inside my head, here’s some M32 x 1.5 brass bar I was threading last night. This is actually to make 40 threaded brass heat sinks but I figured it would be easier to thread the entire length then cut in the band saw to size before facing and drilling holes for wiring to pass through.