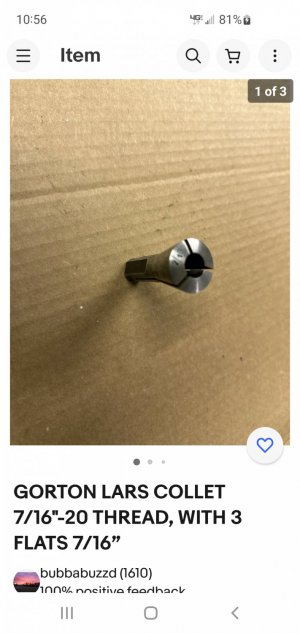

I am attempting to make a 1/2 inch collet for my Gorton mill. The Gorton collets are rare and special in design. They have 3 flats on the draw bar end and have a 10 degree taper. I have already made an arbor for end mill and now working on a collet. The slit in the collet is .040 inch and I am using 1144 stress proof. I'll graduate to a heat treated spring steel material later.

I'll have to slit the collet after machined to size and am wondering what slitting saw blade to use. The big end of the collet taper is 1 inch so the section to cut through in 1/4 inch maximum. Once I get an appropriate blade, I'll make the blade arbor to fit.

The other issue I have is how to locate the slitting saw so it cuts exactly perpendicular to the circumference.

Any thoughts on this?

I'll have to slit the collet after machined to size and am wondering what slitting saw blade to use. The big end of the collet taper is 1 inch so the section to cut through in 1/4 inch maximum. Once I get an appropriate blade, I'll make the blade arbor to fit.

The other issue I have is how to locate the slitting saw so it cuts exactly perpendicular to the circumference.

Any thoughts on this?