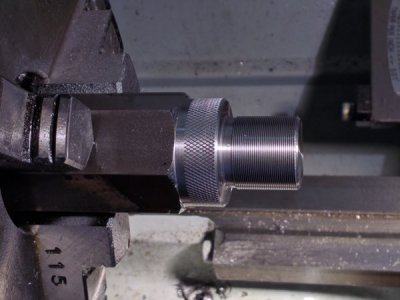

Here is a threading method an old time machinist taught me:

1. Lock in the thread dial at the appropriate number and leave it locked in until the thread is complete.

2. Take a few cuts using the cross slide.

3. At the end of each cut stop the lathe and zero the DRO in X.

4. Bring the cross out a few thousands and put the lathe in reverse.

5. Run the carriage back to the start of the thread.

6. Bring the X back to zero and crank in about .005.

7. Repeat for a few passes then switch to using the compound until the thread is complete.

The nice thing about this method is that it completely eliminates the tedious task of engaging and dis-engaging the lead screw. I use my Monarch 10EE running a carbide threading insert and Viper's Venom for lube. I am producing some excellent threads in the 20-30 TPI range. Haven't tried it on coarse threads but it should work just as well. Best thing about it is not having to deal with the thread dial on each pass.

1. Lock in the thread dial at the appropriate number and leave it locked in until the thread is complete.

2. Take a few cuts using the cross slide.

3. At the end of each cut stop the lathe and zero the DRO in X.

4. Bring the cross out a few thousands and put the lathe in reverse.

5. Run the carriage back to the start of the thread.

6. Bring the X back to zero and crank in about .005.

7. Repeat for a few passes then switch to using the compound until the thread is complete.

The nice thing about this method is that it completely eliminates the tedious task of engaging and dis-engaging the lead screw. I use my Monarch 10EE running a carbide threading insert and Viper's Venom for lube. I am producing some excellent threads in the 20-30 TPI range. Haven't tried it on coarse threads but it should work just as well. Best thing about it is not having to deal with the thread dial on each pass.