I've made a lot of progress on this build, and I've decided to do a build thread by continuing on here. I have learned a lot during the design and build phase and I thought some of this may be helpful to others.

I've actually had the mill mostly assembled and tested and have taken it apart to paint it. So, I thought I would document the reassembly process. I did take some pictures as I was designing and building various components so I'll try to include those as I go. I have made some changes along the way such as converting to a AC Servo for the spindle drive and I'll document my learnings in regard to things like that.

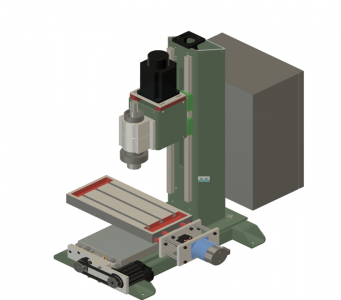

So, for a late introduction, here is what I'm doing.

Not sure how often I'll post as life does tend to prioritize things for you!

As they say "some assembly required"......

![IMG_1237[1].JPG IMG_1237[1].JPG](https://www.hobby-machinist.com/data/attachments/409/409163-db0bd451941ca3abbab078da259dc2e7.jpg)

![IMG_1238[1].JPG IMG_1238[1].JPG](https://www.hobby-machinist.com/data/attachments/409/409164-100331beed09c426b19abefbfa8b2f2e.jpg)

I've actually had the mill mostly assembled and tested and have taken it apart to paint it. So, I thought I would document the reassembly process. I did take some pictures as I was designing and building various components so I'll try to include those as I go. I have made some changes along the way such as converting to a AC Servo for the spindle drive and I'll document my learnings in regard to things like that.

So, for a late introduction, here is what I'm doing.

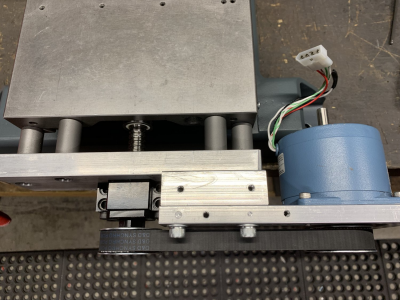

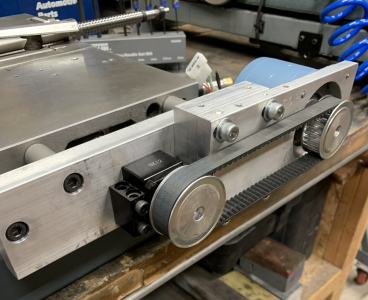

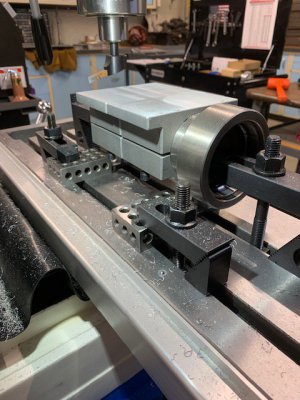

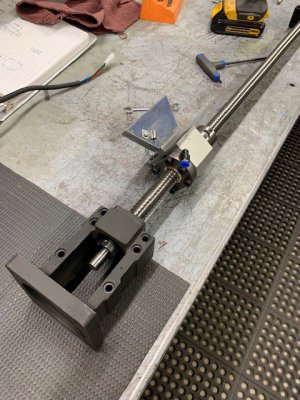

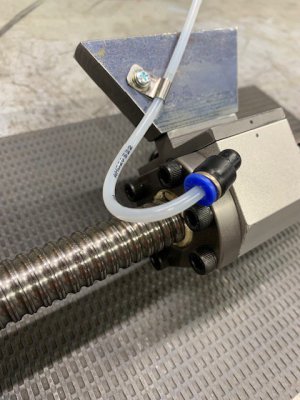

- I found a nice XY table on Craigslist which was the motivation for this build. It is a Fehlman table made in Switzerland, so it is very accurate and good basis to start with. I've converted it to ballscrews and extended the travel a bit too.

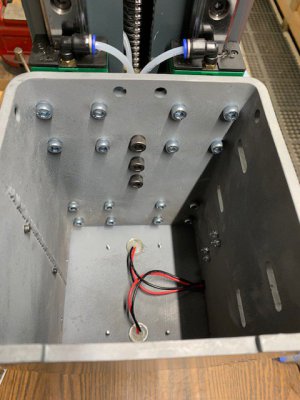

- The base is 3" square tube with 1/4" wall. It is welded together with a 3/8" thick plate on top for the column to mount to. It is very sturdy.

- The column is a 6" square tube with 3/8" wall, very heavy. I found this at my local steel supplier in the drop area. It looked like the perfect size and I used it as I found it without having to cut it. The angle at the top was already there. Its about 38" tall and allows for 16" of Z axis travel.

- I'm using a Centroid Acorn controller and some open loop stepper drives and motors I have accumulated over the years. I may eventually upgrade to closed loop steppers if I have to.

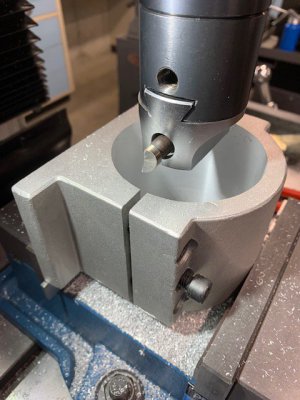

- The spindle came off of a Smithy Granite combo machine, which is now just a lathe. It uses R8 collets and uses angular contact bearings, which I have replaced.

- The spindle drive is an import AC Servo rated at 1.5KW and 3000 RPM. I've geared the spindle belt 1 to 1 so I can do rigid tapping.

Not sure how often I'll post as life does tend to prioritize things for you!

As they say "some assembly required"......

![IMG_1237[1].JPG IMG_1237[1].JPG](https://www.hobby-machinist.com/data/attachments/409/409163-db0bd451941ca3abbab078da259dc2e7.jpg)

![IMG_1238[1].JPG IMG_1238[1].JPG](https://www.hobby-machinist.com/data/attachments/409/409164-100331beed09c426b19abefbfa8b2f2e.jpg)

Last edited:

![IMG_1283[1].JPG IMG_1283[1].JPG](https://www.hobby-machinist.com/data/attachments/410/410250-953dca35d4353c9fdedfbe5ff2d0295a.jpg)

![IMG_1254[1].JPG IMG_1254[1].JPG](https://www.hobby-machinist.com/data/attachments/410/410243-95207c669ed567a9113e617890111667.jpg)

![IMG_9007[1].JPG IMG_9007[1].JPG](https://www.hobby-machinist.com/data/attachments/410/410242-0a9f44ad08b51de8d07970aab3111537.jpg)

![IMG_1260[1].JPG IMG_1260[1].JPG](https://www.hobby-machinist.com/data/attachments/410/410251-4beffe97c064fbd6e1ad1928b3b96983.jpg)

![IMG_1261[1].JPG IMG_1261[1].JPG](https://www.hobby-machinist.com/data/attachments/410/410252-6b5fd5726bf27f3094237ac17e45e5d7.jpg)

![IMG_1282[1].JPG](/data/attachments/410/410248-24d9dd5268fb1b465ac0c1d8a0af2226.jpg)

![IMG_1256[1].JPG](/data/attachments/410/410246-a5ed4cc54b3c2713390c3cd7fcbf5f04.jpg)

![IMG_1257[1].JPG](/data/attachments/410/410244-d6844b6830dd572e3c76d3a8b039a314.jpg)

![IMG_0953[1].JPG IMG_0953[1].JPG](https://www.hobby-machinist.com/data/attachments/411/411644-8c817e9fd075ee275ee784579ea7ffde.jpg)

![IMG_1225[1].JPG IMG_1225[1].JPG](https://www.hobby-machinist.com/data/attachments/411/411645-6238d395283f62788232dd8b65f4f6c3.jpg)

![IMG_0960[1].JPG IMG_0960[1].JPG](https://www.hobby-machinist.com/data/attachments/411/411649-5c1feec7c4371d8946e6aaf15f4a96f4.jpg)

![IMG_1232[1].JPG IMG_1232[1].JPG](https://www.hobby-machinist.com/data/attachments/411/411647-b864ccc8ec950f67b18d808b4fabe846.jpg)

![IMG_1231[1].JPG IMG_1231[1].JPG](https://www.hobby-machinist.com/data/attachments/411/411648-73dc0bd458398aa4c3dd72b0630a6d8e.jpg)

![IMG_1400[1].JPG IMG_1400[1].JPG](https://www.hobby-machinist.com/data/attachments/412/412623-60b55694357be51e70eae8d0669960dc.jpg)