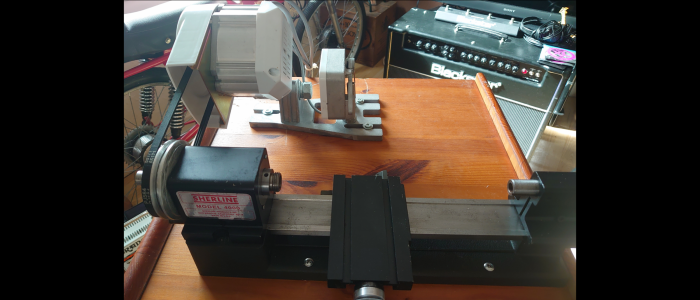

I have recently started trying to use the Sherline lathe that I inherited from my Dad. I'm completely new to this and starting with the most basic cuts.

I chucked some 6061 aluminum stock that I got from Amazon. Roughly 2.5 inches long and an inch in diameter. I was trying to do a basic right to left cut.

The "first cut" section of the manual talks about taking fairly aggressive cuts from the stock (up to 50 thousands). What I found was that I could make a 5 thou cut fairly easily and a 10 thou with some concern, but at 15 thou, it was less than .100 down the material when the material would grab the cutter and climb it, wrenching it out of alignment.

Today I picked up an optical tach to verify that my speeds were about right.

I also center drilled the tail and set up a live center to support the tail. Then I could make much better cuts (did .035 before I quit for the night).

So, my question is: is this normal? The sample cut videos on the Sherline site don't show a tail support, but the piece is both shorter and thinner.

If it is normal, how do people support the tail when facing it off?