- Joined

- Aug 29, 2019

- Messages

- 556

Here I am humbly asking for guidance for re machining a VEE Way on my lathe saddle. I was busy studying girls in math class so here I am at age 72 and have forgotten what I learned from girls.

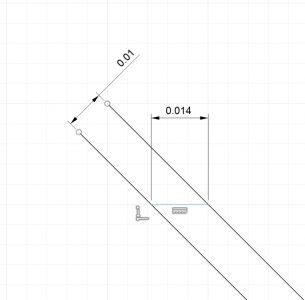

Okay nuff of the funny stuff. So imagine a VEE and you want to take .050 per side of the VEE off in multiple passes with a 70-degree end mill. (35 degrees per side of the end mill) Machining only one side first and then moving to the other side and repeating the same. I am seeking a formula to arrive at how many thou of down/ZEE travel and how many Y travel to achieve .010 depth of cut on each pass. So I am asking for a simple dumbed down explanation to do the math. Or even butter an online calculator that will do the math for me. Thanks in advance.

Okay nuff of the funny stuff. So imagine a VEE and you want to take .050 per side of the VEE off in multiple passes with a 70-degree end mill. (35 degrees per side of the end mill) Machining only one side first and then moving to the other side and repeating the same. I am seeking a formula to arrive at how many thou of down/ZEE travel and how many Y travel to achieve .010 depth of cut on each pass. So I am asking for a simple dumbed down explanation to do the math. Or even butter an online calculator that will do the math for me. Thanks in advance.

Last edited: