- Joined

- Dec 25, 2011

- Messages

- 10,552

Artemetra,

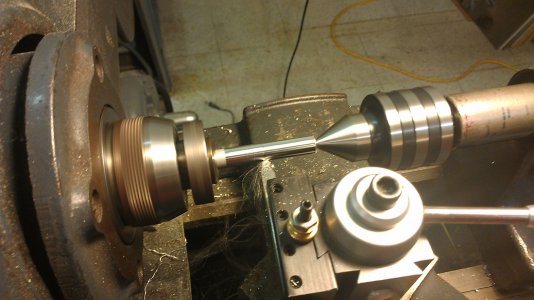

Thanks for the photos. That is a fair amount of length difference. But about the same as the max delta-L out of the assortment of 60 odd collects that I have. For reference, all three of the collet drawings that I have agree that the length from the left (threaded) end to the large end of the taper should be 2-5/16" AKA 2.313".

However, if that amount means the difference between working and not working, the spacer/pilot/thrust bearing next to the handwheel on your closer is too short or thin for your spindle. I have three handwheel type collet closers. Two are Atlas originals, one early and one late, that I finally found after some time looking. The first one that I bought has the handwheel and spacer adjustable. So I can use it on 3AT or 3C collets. My rule-of-thumb for adjusting it is that when the draw tube is screwed about half-way onto the collet (typically 7 or 8 threads) the pilot should be against the end of the spindle and the collet should be fully in the adapter but not squeezed any. If you make a spacer to go between the thrust bearing and the wheel of a thickness such that the above rule is met for the rest of your collets, the Precision ones will work fine. You will probably need longer flat head screws.

Robert D.

Thanks for the photos. That is a fair amount of length difference. But about the same as the max delta-L out of the assortment of 60 odd collects that I have. For reference, all three of the collet drawings that I have agree that the length from the left (threaded) end to the large end of the taper should be 2-5/16" AKA 2.313".

However, if that amount means the difference between working and not working, the spacer/pilot/thrust bearing next to the handwheel on your closer is too short or thin for your spindle. I have three handwheel type collet closers. Two are Atlas originals, one early and one late, that I finally found after some time looking. The first one that I bought has the handwheel and spacer adjustable. So I can use it on 3AT or 3C collets. My rule-of-thumb for adjusting it is that when the draw tube is screwed about half-way onto the collet (typically 7 or 8 threads) the pilot should be against the end of the spindle and the collet should be fully in the adapter but not squeezed any. If you make a spacer to go between the thrust bearing and the wheel of a thickness such that the above rule is met for the rest of your collets, the Precision ones will work fine. You will probably need longer flat head screws.

Robert D.