I managed to pick up a Logan 825 on CL for less than scrap value. It had been disassembled by some previous owner many years ago and the guy I bought it from was just trying to clean the place out and didn't want it thrown away. For the sum of $25 I came home with ~300lbs of cast iron. As far as I can tell, most of the parts are there (Bed, head-stock, tail-stock, carriage, QCGB, etc.). Some parts are rusty, others are slathered in paint, and some have been spray painted red??? It really is a basket case, but I'm going to work through and see if I can get it back together and give it a little TLC.

One of the issues I've encountered right away is that it was made to be mounted on Logan's stand with the motor mounted underneath. Since I don't have the stand and locating one would be a significant challenge, I'm trying to get creative. I have a spare 3/4hp Baldor motor that would suit it, but without the intermediate jack-shaft, it would only be one speed and much too fast. I've seen some people using permanent magnet DC motors on lathes so that they have speed control. Would one of these have sufficient power to run the lathe with a smallish single reduction? Obviously I'd need something bigger than the treadmill motor others use on the 7" mini-lathe.

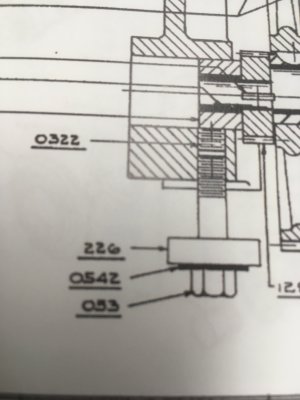

Does anyone have any pictures of how the head-stock is mounted to the bed? There are two bolt holes on the chuck side of the head-stock that look like they would clamp it to the bed with some sort of bar underneath. I don't see any provision for a clamp on the back side of the head-stock. The .pdf manual I found on Vintage Machinery seems to show mounting points on the front and rear.

Thanks for any help or guidance you can provide.

One of the issues I've encountered right away is that it was made to be mounted on Logan's stand with the motor mounted underneath. Since I don't have the stand and locating one would be a significant challenge, I'm trying to get creative. I have a spare 3/4hp Baldor motor that would suit it, but without the intermediate jack-shaft, it would only be one speed and much too fast. I've seen some people using permanent magnet DC motors on lathes so that they have speed control. Would one of these have sufficient power to run the lathe with a smallish single reduction? Obviously I'd need something bigger than the treadmill motor others use on the 7" mini-lathe.

Does anyone have any pictures of how the head-stock is mounted to the bed? There are two bolt holes on the chuck side of the head-stock that look like they would clamp it to the bed with some sort of bar underneath. I don't see any provision for a clamp on the back side of the head-stock. The .pdf manual I found on Vintage Machinery seems to show mounting points on the front and rear.

Thanks for any help or guidance you can provide.