- Joined

- Nov 25, 2015

- Messages

- 10,041

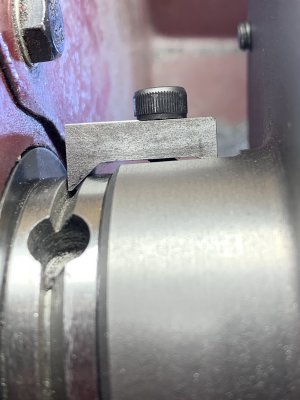

I drilled my chucks and spindle. In the spindle I have a drilled hole for a dog point set screw. I used to have a brass set screw, but this is more positive. I still need to take light cuts. On my Bison there was not a lot of room for the screw, so it's small... don't remember, maybe a 10-32. I put the dogpoint on the set screw. you don't need a dogpoint, only for the screw to seat down, I didn't want to have a problem with the screw when I want to back it out.I just acquired my first lathe (SouthBend heavy 10L) that has a threaded spindle to attach the chuck and other equipment. I have heard never to try using this lathe in reverse as this will unthread the chuck. Is there a safe way to use this machine in reverse?