- Joined

- Sep 10, 2020

- Messages

- 52

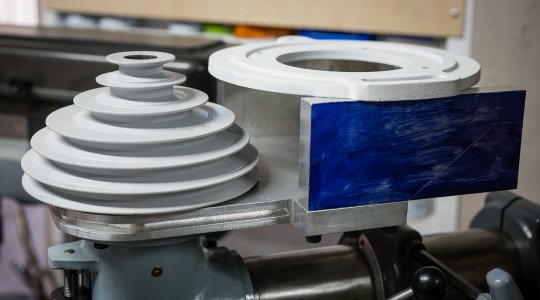

The pulley bearings are installed and in the photo is my version of the bearing lock nut wrench to tighten it all together. This is a simple 1 1/4" cast iron pipe coupler machined down to size. It isn't a hardened socket or anything and I wondered if the cast iron would crack under load, but it worked nicely. Those expensive 2 pairs of duplex bearings were class ABEC 7 and the upper spindle bearing MRC R16FF is ABEC 1. I don't recall seeing any other options on that bearing when I ordered.

What the items are sitting on in the photo is a blank canvas as they say. It is aluminum 9" wide and 10" long by 3/4" thick, marked up and ready go. This will be the foundation of the pulley housing. If my vision works out, it will be quite distinctive.

What the items are sitting on in the photo is a blank canvas as they say. It is aluminum 9" wide and 10" long by 3/4" thick, marked up and ready go. This will be the foundation of the pulley housing. If my vision works out, it will be quite distinctive.

In case you wanted even more stuff to do...

In case you wanted even more stuff to do...