-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Request For An HSS Lathe Cutter Primer for Boring Bars

- Thread starter WCraig

- Start date

- Joined

- Oct 11, 2016

- Messages

- 4,008

I wanted to clean up one thing on the carbide issue. Many carbide tools holders are negative rake, but you can still find some positive rake inserts for negative rake holders... An insert/holder combination that ends up with a negative rake cutting surface does need a significant depth of cut to cut well and or evenly.

Holders with inserts that end up wit a positive rake cutting surface and a well honed an sharp cutting edge can take shallow cuts well and cut accurately. On most small hobby machines these positive rake combinations are well suited for many materials.

Holders with inserts that end up wit a positive rake cutting surface and a well honed an sharp cutting edge can take shallow cuts well and cut accurately. On most small hobby machines these positive rake combinations are well suited for many materials.

Wether it be hss or carbide I think it comes down to tool geometry and the holder is part of that geometry. Working with hss has given me knowledge to understand tool geometry to help me understand my carbide purchase and it is still my main source of tooling for costs and the fact I can modify if need be. It can be daunting choosing a carbide tool. There is a line where the power and mass is need to turn that cut into a hot knife going through butter. It pulverises metal and changes it s characteristics and allows it to make the cut. Smaller machines don t have that ability to make the change in the metal with the negative rake style tools. It may frustrate you but you ll be better on the other side to work with hss for sometime. Just my opinion!

I love rake with my hss except with flycutters to remain on centre on regrinds.

I love rake with my hss except with flycutters to remain on centre on regrinds.

- Joined

- Oct 10, 2018

- Messages

- 545

As I mentioned, I was following an auction with a tonne of machining tools. I ended up with a few lots including the boring tools I mentioned earlier in this thread. All the cutters are HSS; no carbide. In this post, I've got a few pictures of the tools I plan to keep...along with some questions.

The two on the left mount in a 3/8" holder but are very slim and can start in very small holes. I've already used the larger of these in a little project. It cut aluminum very nicely. However, I did notice that many of the chips were ejected forward from the bit and ended up clogged in the chuck. Is that common?

The centre two are basic steel boring bars. The smaller takes 1/8" bits and the larger 3/16". The have square and angled recesses at either end of the bars. The holder on the smaller bar is the same as the one in the quick change tool holder (0XA).

The two on the right are intriguing. The shank is 3/8" diameter and will therefore fit the holders to the left. The bits are round (6mm diameter on the smaller and 8mm on the larger) with a flat milled on the top. I believe they came sharpened from the factory. The points are about 55 degrees and extend past the end of the holder. I believe you could start with a VERY small pilot hole and widen it as much as you wanted. You could go about as deep as the length of the body of the holder. Looks like it would be good for making a recess with a square shoulder. These two don't seem to have ever been used. I think the bits need honing first.

Craig

The two on the left mount in a 3/8" holder but are very slim and can start in very small holes. I've already used the larger of these in a little project. It cut aluminum very nicely. However, I did notice that many of the chips were ejected forward from the bit and ended up clogged in the chuck. Is that common?

The centre two are basic steel boring bars. The smaller takes 1/8" bits and the larger 3/16". The have square and angled recesses at either end of the bars. The holder on the smaller bar is the same as the one in the quick change tool holder (0XA).

The two on the right are intriguing. The shank is 3/8" diameter and will therefore fit the holders to the left. The bits are round (6mm diameter on the smaller and 8mm on the larger) with a flat milled on the top. I believe they came sharpened from the factory. The points are about 55 degrees and extend past the end of the holder. I believe you could start with a VERY small pilot hole and widen it as much as you wanted. You could go about as deep as the length of the body of the holder. Looks like it would be good for making a recess with a square shoulder. These two don't seem to have ever been used. I think the bits need honing first.

Craig

- Joined

- Oct 10, 2018

- Messages

- 545

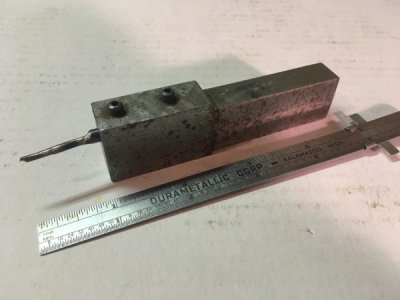

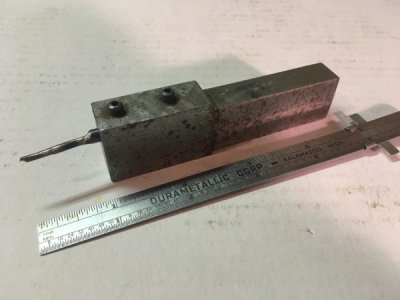

This post is about the boring tools I got in the auction but don't plan to keep. All of the holders are too big for my 0XA quick change tool holding system. Before the auction, I knew that the bigger tools weren't going to be compatible. I didn't realize that the smaller ones (especially the two at the left) were just a fraction too large. The two on the left are both 14mm square and the next two holders are 15.75 mm square. The fifth from the left is 19mm square holding a 14mm bar.

I'm unfamiliar with the toolholder at right. It seems to be an extension bar (?) that might either fit in a larger QCTP system OR in an old-school lantern tool post? The picture doesn't show it, but it will securely hold either 1/8" or 1/4" tool bits. It is pictured with a random 1/4" bit that came in another lot. There are no marks on it to indicate that it was ever actually used. However, the bar is 11.6 by 18 mm so it is too big to fit anything on my machine. Can someone explain what this kind of holder is typically used for?

There was also a user-made holder for a lantern-style tool post. It is too big for anything on my lathe but holds a little 3/16" round tool bit.

Craig

I'm unfamiliar with the toolholder at right. It seems to be an extension bar (?) that might either fit in a larger QCTP system OR in an old-school lantern tool post? The picture doesn't show it, but it will securely hold either 1/8" or 1/4" tool bits. It is pictured with a random 1/4" bit that came in another lot. There are no marks on it to indicate that it was ever actually used. However, the bar is 11.6 by 18 mm so it is too big to fit anything on my machine. Can someone explain what this kind of holder is typically used for?

There was also a user-made holder for a lantern-style tool post. It is too big for anything on my lathe but holds a little 3/16" round tool bit.

Craig

- Joined

- Oct 11, 2016

- Messages

- 4,008

Yes, it is very common for boring bars to eject the swarf into the hole.... Newer carbide inserts are configured to direct much of the swarf out of the hole - but a lot stays in anyway - it's a part of regular boring -cleaning out the hole...

The tool on the right is an adapter for HSS bits in a lantern or nXA tool holder, depending on the dimensions.

The tool on the right is an adapter for HSS bits in a lantern or nXA tool holder, depending on the dimensions.

- Joined

- Dec 20, 2012

- Messages

- 9,422

I've already used the larger of these in a little project. It cut aluminum very nicely. However, I did notice that many of the chips were ejected forward from the bit and ended up clogged in the chuck. Is that common?

Not sure who made that bar in the quick change holder but it is a positive rake tool. All boring bars tend to cut stringy chips, especially if you feed too slow. As with all positive rake tools for aluminum, deeper depths of cut and faster feed rates will minimize this tendency. Coolant, like WD-40, also helps.

- Joined

- Jun 1, 2018

- Messages

- 154

Duke how long will it take for a guy who has just learnt to watsap on his smart phone and borrows his wifes laptop to go on hobby machinest to learn how to draw those nice green tools you posted.? . Do you draw for part of your job or are you self taught and what programme do you use.

. Do you draw for part of your job or are you self taught and what programme do you use.