- Joined

- Dec 6, 2011

- Messages

- 217

Continued from "Map Errors on Older Lathe".

The RD14X40 has a monster of a stiff bed. Very deep and well bolstered with large cross members.

After some careful comparison with a good precision level (Mitutoyo .0006/12") I have some twist in my

lathe bed. I have not quantified the difference at this point. I am getting a appreciable amount of taper

with the diameter increasing as the distance from the chuck increases (like .005 in 1.5 "). When i put the

level under the chuck(same place each time) and level the lathe across the bed, then move the level to the

tail end, the back side of the bed at the tailstock end is off the scale out of level high. According to good solid

information (and logic) , this can contribute to the tapering problem. After taking the twist out, I will look

at other factors such as spindle alignment (head nod , ect.).

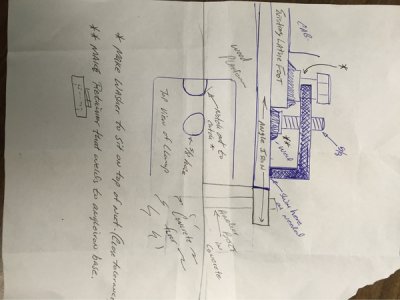

I have "bedded" the lathe to the concrete floor. I am now making some "clamps" to hold the feet in place

when I need to pull down on a lathe foot-pad. The lathe is so stiff that if you shim up on the head-stock

backside feet, the whole back side including the tailstock end will lift. I plan to adjust this very slowly to

achieve level. When I get one completed I will post a photo and report success or failure.

The RD14X40 has a monster of a stiff bed. Very deep and well bolstered with large cross members.

After some careful comparison with a good precision level (Mitutoyo .0006/12") I have some twist in my

lathe bed. I have not quantified the difference at this point. I am getting a appreciable amount of taper

with the diameter increasing as the distance from the chuck increases (like .005 in 1.5 "). When i put the

level under the chuck(same place each time) and level the lathe across the bed, then move the level to the

tail end, the back side of the bed at the tailstock end is off the scale out of level high. According to good solid

information (and logic) , this can contribute to the tapering problem. After taking the twist out, I will look

at other factors such as spindle alignment (head nod , ect.).

I have "bedded" the lathe to the concrete floor. I am now making some "clamps" to hold the feet in place

when I need to pull down on a lathe foot-pad. The lathe is so stiff that if you shim up on the head-stock

backside feet, the whole back side including the tailstock end will lift. I plan to adjust this very slowly to

achieve level. When I get one completed I will post a photo and report success or failure.

Last edited: