Hi guys, just wanted to throw in my thanks and experience here for future ref. I was in the same boat with this cheap chuck. TIR was about 0.007" if I mounted it a couple of different ways but I was able to achieve a 0.0045" if mounted in one particular cam lock configuration (which I promptly marked with a center punch on the outside).

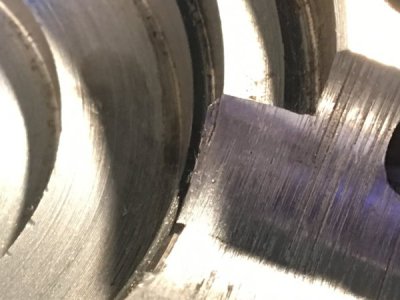

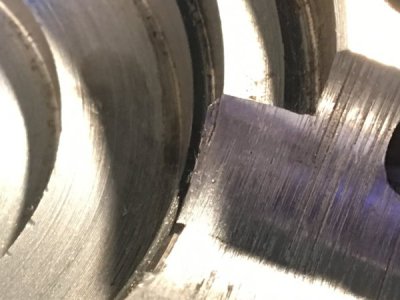

I took apart the chuck which in and of itself was a b and a half as the two halves were on insanely tight. I found tons of crud and enough burrs to make Hamilton turn over in his grave. It appears they first put the two halves together and machine them together while mated, then they drill the side scroll holes and leave it as is. Meaning any burrs and chips from the drilling are left inside for us to enjoy. Anyway, I figured that after cleaning it out and putting it back together I'd come close to what the advertised tolerance is. But no such luck.

The good news is that the chuck consistently gave me the same 0.0045" TIR on the inside of the spindle nose (and less than 0.0005" when measured on the first half). So I took the leap and ground it with my dremel attachment and voila. <0.0005" TIR at the edge of the collet and about 0.001" about 0.25" away. I only took 0.002" off which is probably why the 0.0005" TIR remains but it's good enough for me. If I ever need more accurate I figure I'll just get on the 4-jaw. Including some pictures for posterity.

If I would've know what I'd gotten myself into before I purchased it is have gone with a plane back and made my own D1-4 to mate it onto and saved myself the stress.

I took apart the chuck which in and of itself was a b and a half as the two halves were on insanely tight. I found tons of crud and enough burrs to make Hamilton turn over in his grave. It appears they first put the two halves together and machine them together while mated, then they drill the side scroll holes and leave it as is. Meaning any burrs and chips from the drilling are left inside for us to enjoy. Anyway, I figured that after cleaning it out and putting it back together I'd come close to what the advertised tolerance is. But no such luck.

The good news is that the chuck consistently gave me the same 0.0045" TIR on the inside of the spindle nose (and less than 0.0005" when measured on the first half). So I took the leap and ground it with my dremel attachment and voila. <0.0005" TIR at the edge of the collet and about 0.001" about 0.25" away. I only took 0.002" off which is probably why the 0.0005" TIR remains but it's good enough for me. If I ever need more accurate I figure I'll just get on the 4-jaw. Including some pictures for posterity.

If I would've know what I'd gotten myself into before I purchased it is have gone with a plane back and made my own D1-4 to mate it onto and saved myself the stress.