- Joined

- Dec 15, 2014

- Messages

- 285

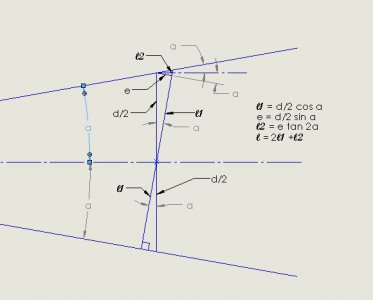

Bob actually the sine bar was part of the first solution that had the problem of the centerline axis alignment issue. I suggested to use the sine bar for this solution simply because it has a fixed stop for the small end of the cone and the gage pins to seat against. I am sure that having the cone on a surface plate with the small end face against the inside of one leg of a ground or granite angle and the large o.d. touching the other inside leg yields the same result with the possible exception that the gage pins would not be at right angles to the cone horizontal centerline. By using a sine bar and approximating a gage stack the horizontal plane of the centerline of the cone would be closer to 90 degrees to the vertical standing gage pins and maybe that is not a issue. The key being a 90 degree angle on the inside corner of the angle plate and the gage pins, and cone equaling the large end o.d. Also are you familiar with the use of the two different dia pins a given distance apart to measure a angle as I mentioned in my previous post? I will see if I can find a example on the net. I truly am computer illiterate And as I post Randy lists one example of what I describe. Thanks Randy. When in doubt go to the Handbook! I could have saved you both some typing and head scratching. lol

Darrell

Darrell