- Joined

- Dec 15, 2014

- Messages

- 285

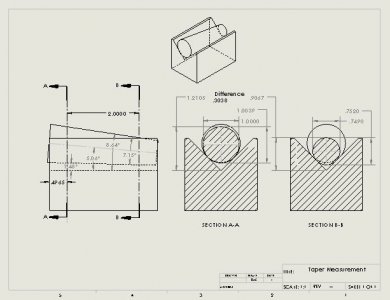

That is a lot of interesting data regarding tolerance standards...too much for this old guy though. I again find it interesting that we with home shops think we can chase tolerances that in reality we cannot even check. A grade B cheapo surface plate or non calibrated blocks that many of us own aren't capable of giving that accurate of measurement. certainly at least in a uncontrolled temperature environment. Measuring a existing taper, turning, bluing and possibly filing or sanding has always been the homeshop and even some job shops mode of making a satisfactory taper but then we are not held to ISO standards. If a morse taper for example seats, blues well and holds tight then it is good enough in my world. Making such a taper by my method would not possibly pass a qc inspection because a file or emery cloth automatically would cause a part to fail in concentric spec if nothing else. To make a ISO quality taper would require the part to be ground. You do not see commercially made ISO quality parts finished by turning, at least I haven't. Randy C has shown a often good enough example using 123 blocks. RJ Sakowski has shown the proper way using CAD. Both with far better explanations and a better grasp of trig than I have. If I had the need for a accurate measurement of a taper using Randy's second suggestion I would put the tapered part on a sine bar and put what I thought was a correct approximation of gage blocks under the bar. At that point I would use Randy's method of traversing the taper with a dti. If it read zero (unlikely) you would know the taper by using your gage block height to do the math. If it isn't zero then you would have to do the trig for the resulting difference. If I just needed to make a part to satisfy my needs I use Randy's method. If I were to need something more accurate RJ Sakowski's CAD and Tormach programs are the cats pajamas. But if I really needed that good of part and knew it had to meet the above tolerances, Hell I would just send it out to be ground. Thank you both for great descriptions.

Darrell

Darrell