-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Quarantine Projects!

- Thread starter Weldo

- Start date

- Joined

- Sep 7, 2019

- Messages

- 674

Well here's a prime example of what happens when you have too much time on your hands...

You spend over an hour making tiny parts that you could easily purchase for pennies from almost any store in the country.

I needed some snap swivels for model rocket parachutes. I had a few swivels but no snaps so I got to work!

Here was my inspiration, mostly the big silver one.

The three on the left are made from 0.030" stainless MIG wire. The two on the right are made from an old DIY fishing spinner kit. The idea is that you'd take a swivel wire like on the far right there and add some beads, spoons and a treble hook at the end to make your own lures. The wire is brass.

Close up of the stainless ones. The left was the first one I did and the right is the last. The middle one is like that cousin you have that "Ain't quite right." I've named it Cletus. The last one is pretty good.

Overall they came out well. Ultimate strength is quite strong. Easily strong enough for a small model rocket. They don't spring open very well though since the wire is not a hardened spring steel.

These are the brass wire ones from the spinner kit. They seem strong enough but are even less springy than the stainless ones.

This was an exercise in patience I'll tell ya! All I used were two pairs of small needle nose pliers and some side cutters.

You spend over an hour making tiny parts that you could easily purchase for pennies from almost any store in the country.

I needed some snap swivels for model rocket parachutes. I had a few swivels but no snaps so I got to work!

Here was my inspiration, mostly the big silver one.

The three on the left are made from 0.030" stainless MIG wire. The two on the right are made from an old DIY fishing spinner kit. The idea is that you'd take a swivel wire like on the far right there and add some beads, spoons and a treble hook at the end to make your own lures. The wire is brass.

Close up of the stainless ones. The left was the first one I did and the right is the last. The middle one is like that cousin you have that "Ain't quite right." I've named it Cletus. The last one is pretty good.

Overall they came out well. Ultimate strength is quite strong. Easily strong enough for a small model rocket. They don't spring open very well though since the wire is not a hardened spring steel.

These are the brass wire ones from the spinner kit. They seem strong enough but are even less springy than the stainless ones.

This was an exercise in patience I'll tell ya! All I used were two pairs of small needle nose pliers and some side cutters.

- Joined

- Sep 7, 2019

- Messages

- 674

Knocked out another small one!

I've been working on a straight edge for my old Whitney bench shear for a while. I made a bar, drilled and tapped the shear and picked up some shoulder bolts. Unfortunately between inaccuracies from the hole drilling, when the bar was bolted on it was well out of square.

It was maybe 3/16" out of square over 6 inches. I didn't feel like grinding it so I used the milling attachment on the lathe. I just worked to a scribed line, no indication at all.

As far as milling set ups go this is probably in the "Do not do" section of the machinist handbook. Because i had such limited cross slide travel I had to let over half the part float out in space with no support. It actually went very well though. I took very light cuts.

This is what I was aiming for. Straight edge guide for the shear.

The bar has a tiny bit of play when bolted on. Even though I used shoulder bolts and reamed the holes to 0.375". After it snugged it onto the shear I started making test cuts in some 16ga scrap, making micro adjustments with a dead blow hammer.

It came in pretty darned close to perfect!

Youtuber This Old Tony made a similar modification to a bench shear where he milled the shear body down and made a nice perfectly flat table to hold the stock you're cutting. I like the idea but I don't have the equipment to make that cut. In my case the shear body tapers downward slightly to the left as you stand in front of it. It'd be nice if it were flat though.

I've been working on a straight edge for my old Whitney bench shear for a while. I made a bar, drilled and tapped the shear and picked up some shoulder bolts. Unfortunately between inaccuracies from the hole drilling, when the bar was bolted on it was well out of square.

It was maybe 3/16" out of square over 6 inches. I didn't feel like grinding it so I used the milling attachment on the lathe. I just worked to a scribed line, no indication at all.

As far as milling set ups go this is probably in the "Do not do" section of the machinist handbook. Because i had such limited cross slide travel I had to let over half the part float out in space with no support. It actually went very well though. I took very light cuts.

This is what I was aiming for. Straight edge guide for the shear.

The bar has a tiny bit of play when bolted on. Even though I used shoulder bolts and reamed the holes to 0.375". After it snugged it onto the shear I started making test cuts in some 16ga scrap, making micro adjustments with a dead blow hammer.

It came in pretty darned close to perfect!

Youtuber This Old Tony made a similar modification to a bench shear where he milled the shear body down and made a nice perfectly flat table to hold the stock you're cutting. I like the idea but I don't have the equipment to make that cut. In my case the shear body tapers downward slightly to the left as you stand in front of it. It'd be nice if it were flat though.

- Joined

- Feb 9, 2017

- Messages

- 5,598

You are really keepin' busy Weldo! Good job. I have 3 grinders. A 6" carbide grinder copy of a Baldor and a Jet 6" with a wire wheel and MultiTool. Those are mounted to my work station toolbox. My 8" bench grinder that I did the Oneway balance on doesn't have a permanent place and the tool rests on it are horrible. But it's great for roughing in tool bits. I'm thinking of a base plate with one of the Harold Hall type tool rest like this one and doing like you and clamping to a bench when needed but in storage otherwise.

Attachments

- Joined

- Sep 7, 2019

- Messages

- 674

Thanks man! These are all things I've been wanting to do for a while. When this quarantine is over my little workshop is gonna be standin' tall!

I'd actually like to have another bench grinder too. I want one set up with a wire on one side and a cloth buffing wheel on the other. It would come in handy a lot I think.

That rest design looks cool. Kind of complicated but very easily adjustable. I never considered a rest that doesn't bolt to the grinder itself. That frees up many design constraints!

I'd actually like to have another bench grinder too. I want one set up with a wire on one side and a cloth buffing wheel on the other. It would come in handy a lot I think.

That rest design looks cool. Kind of complicated but very easily adjustable. I never considered a rest that doesn't bolt to the grinder itself. That frees up many design constraints!

- Joined

- Feb 9, 2017

- Messages

- 5,598

I agree, I don't think I'd need the micro adjusters that rest has.

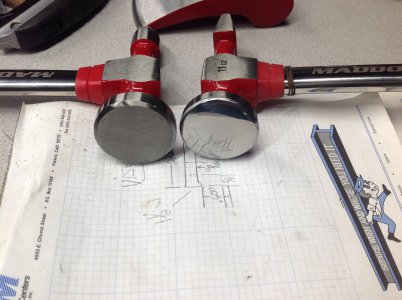

I'd never done any buffing/polishing before so was not sure I'd need it until I decided to modify my cheap HF body hammers. I happened upon a kit MultiTool sells that includes something I'd never heard of, a felt polishing belt. It has several different grits of belts and disk's along with different rouge sticks for the belt. That MultiTool has turned out to be a very handy and versatile unit. I took the cheap body hammer and radiused the face and sides of the face with the grit belts then used the felt belt to polish it. I was shocked how good it came out. It's super quick and easy to change belts on the MultiTool. A before and after.

I'd never done any buffing/polishing before so was not sure I'd need it until I decided to modify my cheap HF body hammers. I happened upon a kit MultiTool sells that includes something I'd never heard of, a felt polishing belt. It has several different grits of belts and disk's along with different rouge sticks for the belt. That MultiTool has turned out to be a very handy and versatile unit. I took the cheap body hammer and radiused the face and sides of the face with the grit belts then used the felt belt to polish it. I was shocked how good it came out. It's super quick and easy to change belts on the MultiTool. A before and after.

Attachments

- Joined

- Feb 9, 2017

- Messages

- 5,598