- Joined

- Feb 23, 2016

- Messages

- 480

Thank you all for the replies. I had a couple of weeks of downtime because of an emergency surgery, then returned to work, so the mill conversion was on a temporary hiatus.

MILL BASE.

I am back now, and have built the base. When I built my CNC router, I used 2x2x.08" tube and welded it all up. Even though I used spot welds in opposite corners, and squared up meticulously everything, etc., heat distortion kicked in, and had to cut up some welds and redo them at the end, to square up everything. I still feel that base is not rigid enough, and will bolt into the ground hoping to improve it; overall, am not very worried about it, as the forces with the router are pretty limited, and with plasma are pretty negligible.

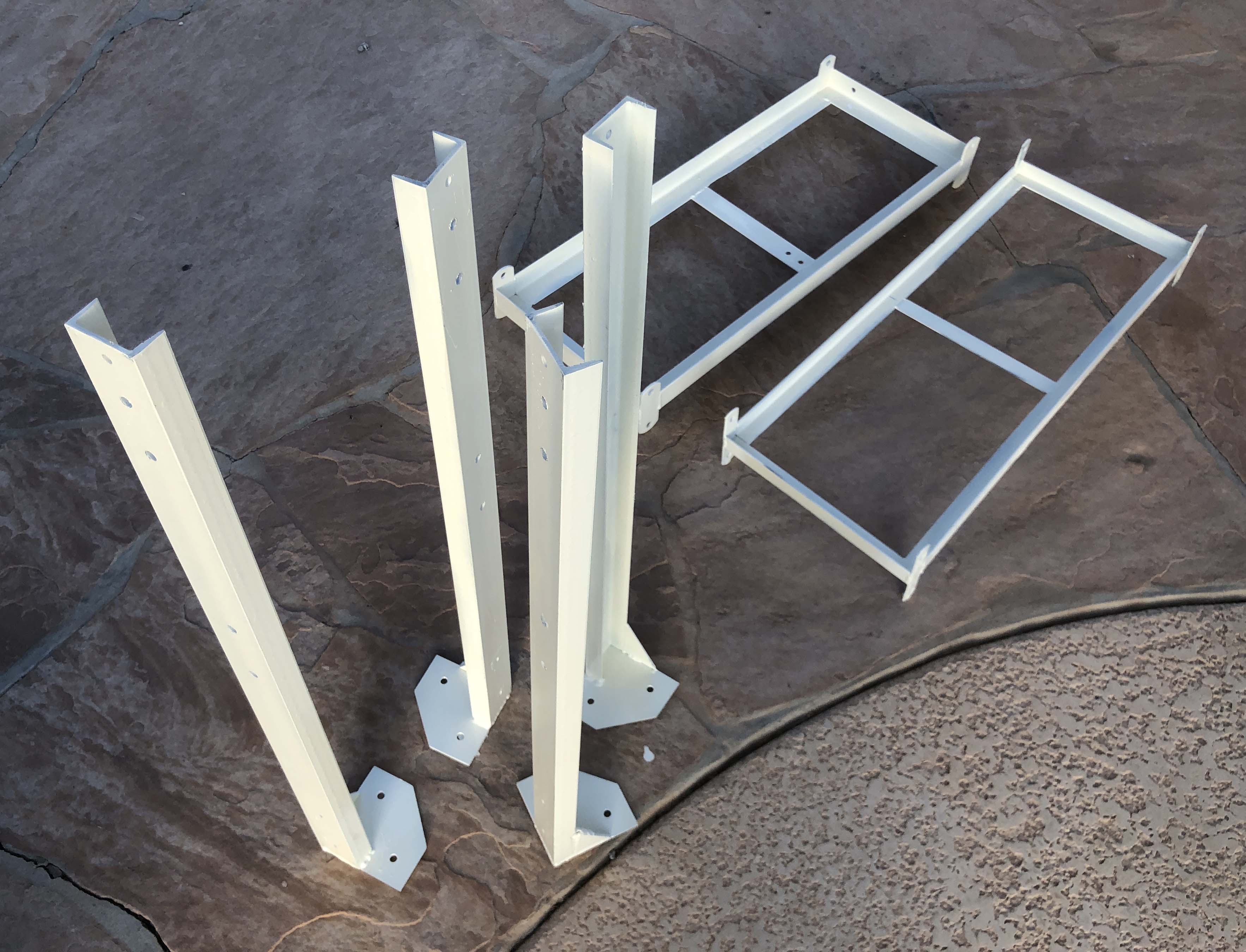

This time I want to make it rigid though, so chose to use an open profile with some corner bracing. Would have used angle if I had enough; although probably not optimal, I ended up using using a 2x1x1/8" channel I had around (and wanted to get rid of) for the top and legs:

I also built a mid-level shelf out of 1.5x1/8" angle to put the coolant tank and pump on:

Finally, I built a bottom shelf using 1x1/8" angle. All this was scrap laying around, happy to get rid of.

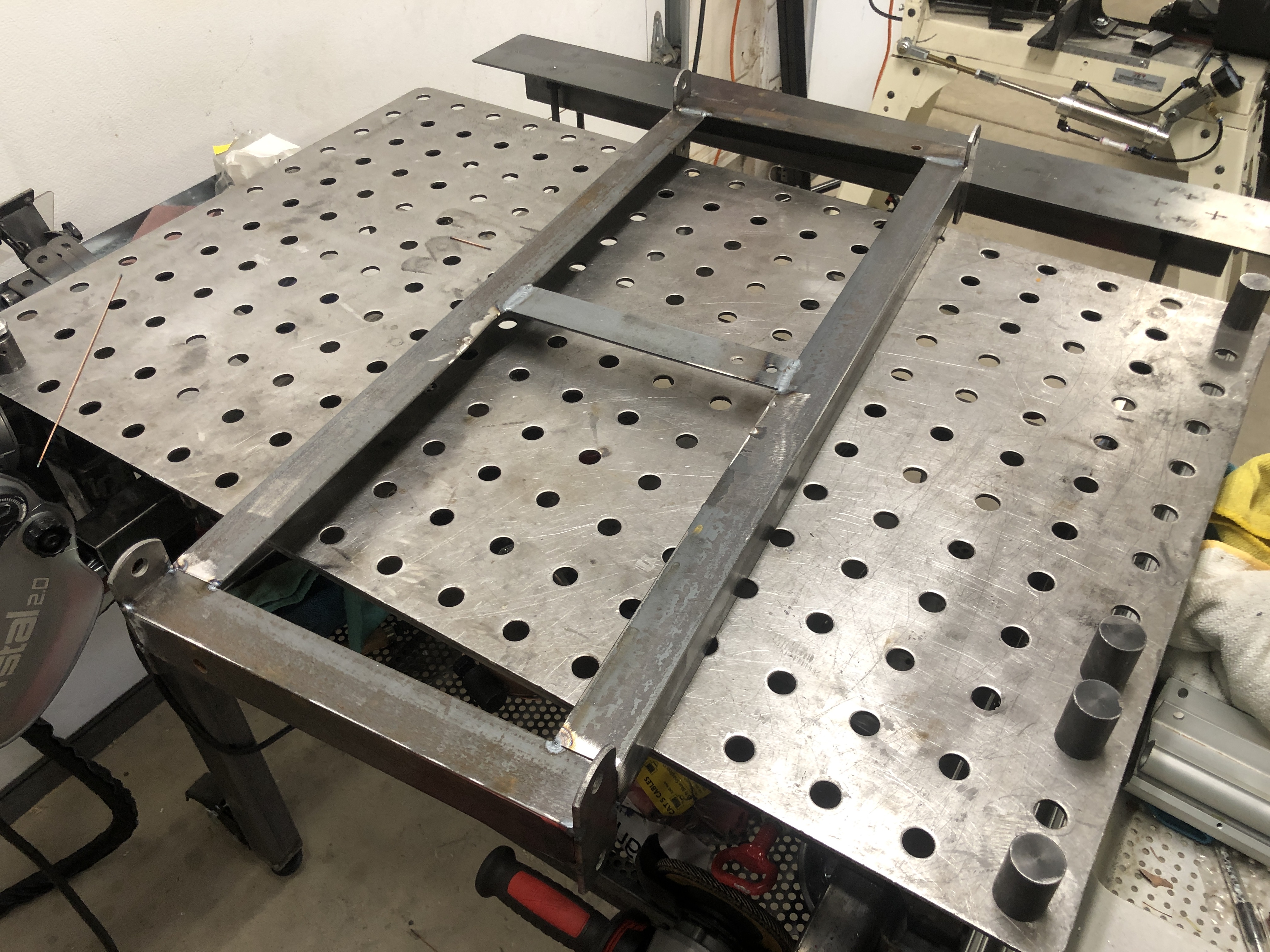

Have decided to bolt it all together with 5/16" bolts mostly (1/4" for the lower shelf and for alignment at top) hoping to get improved dampening, and avoid welding and thus distortion. Will see how it works. here it is during one of the intermediate fitment checks:

Ignore the stiff drink in the image above. Be smarter than me, and do not drink and weld, or you'll end up having welds like mine ;-)

Now all parts are in the backyard, drying its (hopefully) final coat of paint and will assemble it later today.

The base ended up pretty heavy; will bolt it into the concrete floor, hoping it will suffice. Thank you all for the advice above, I will go with 5/16" Tapcons (at least in the first round).

MILL BASE.

I am back now, and have built the base. When I built my CNC router, I used 2x2x.08" tube and welded it all up. Even though I used spot welds in opposite corners, and squared up meticulously everything, etc., heat distortion kicked in, and had to cut up some welds and redo them at the end, to square up everything. I still feel that base is not rigid enough, and will bolt into the ground hoping to improve it; overall, am not very worried about it, as the forces with the router are pretty limited, and with plasma are pretty negligible.

This time I want to make it rigid though, so chose to use an open profile with some corner bracing. Would have used angle if I had enough; although probably not optimal, I ended up using using a 2x1x1/8" channel I had around (and wanted to get rid of) for the top and legs:

I also built a mid-level shelf out of 1.5x1/8" angle to put the coolant tank and pump on:

Finally, I built a bottom shelf using 1x1/8" angle. All this was scrap laying around, happy to get rid of.

Have decided to bolt it all together with 5/16" bolts mostly (1/4" for the lower shelf and for alignment at top) hoping to get improved dampening, and avoid welding and thus distortion. Will see how it works. here it is during one of the intermediate fitment checks:

Ignore the stiff drink in the image above. Be smarter than me, and do not drink and weld, or you'll end up having welds like mine ;-)

Now all parts are in the backyard, drying its (hopefully) final coat of paint and will assemble it later today.

The base ended up pretty heavy; will bolt it into the concrete floor, hoping it will suffice. Thank you all for the advice above, I will go with 5/16" Tapcons (at least in the first round).

Last edited: