Is it the plane you fly in it or you remote control it.My dad wanted a Bridgeport but never got one, he used files and a disk sander to build his airplane.

So yes, it can be done.

Machine tools provide speed, repeatability and greater precision (generally).

Also, CNC can remove many of the inconsistencies involved with human operators. That’s why most production work is done that way now. However, it will benefit you greatly to develop the skill to do fine work with power tools and hand tools.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Power tool vs machine tool

- Thread starter Koi

- Start date

Why hate viceI hate VICE but this is a good one....

- Joined

- May 16, 2016

- Messages

- 1,703

To teach you how important patience and perseverance are. Hated it at the time but many years later glad I did it.For what purpose.

- Joined

- Nov 23, 2017

- Messages

- 1,191

Why hate vice

We are not allowed to talk politics on this website....

- Joined

- Feb 9, 2017

- Messages

- 5,523

I love the turn to the long lost idea of apprenticeships. I'd been holding off because the only guy I know who did a full on apprenticeship was my 80 something old neighbor down the street. I was finally able to find him in his garage tinkering today so I took my phone for some pix and decided to corner him about some specifics.

He had shown me some of his apprentice/journeyman projects his brother had gifted him before he passed. His brother worked as an apprentice instructor at a huge electrical manufacturer in Germany for many years. Horst, my neighbor, was apprenticed in '52 at the age of 16 to a nautical instrument maker in the repair shop. He remembered his project was to square a piece of bronze which he said to do with a file was all but impossible. But he kept at it on the side when he wasn't in class two days a week or working on the shop floor doing stuff for the journeymen or cleaning up. They worked 6 days a week and he made 30 marks a month. The apprenticeship lasted 3 1/2yrs. Because his father had a small shop with many machines and he was already familiar with all of them since he was 5yrs he was never forced to do the very basics.

In that shop they made sextants, the different gauges, thermometers, barometers, and compasses. He stayed there 7yrs in total then went into the aircraft industry making instruments for transports. From there he came to Canada, then the US doing aircraft instruments then ended up in the power generation industry and ended up working for PG&E at the local nuclear powerplant down the road from us. He is very humble about his abilities and makes incredible models of ships and RC aircraft. He also got into clock and watch repair.

Here's some of the apprentice/journeyman projects. The square was all made with files, a drill press and tap. The divider was filed too. Obviously the screw and knob were done with a lathe but notice the fit of the spring. It doesn't look soldered. The little vise is interesting in that it has a dovetail with gibs on the side. Notice too the dovetail is separate and dowel pinned and screwed into place. There is a clamp for clamping to a table. Notice the mortise joint which I think is silver soldered, but it's hard to tell. I know everything is a little rusty but they all have to be at least 60yrs old.

He had shown me some of his apprentice/journeyman projects his brother had gifted him before he passed. His brother worked as an apprentice instructor at a huge electrical manufacturer in Germany for many years. Horst, my neighbor, was apprenticed in '52 at the age of 16 to a nautical instrument maker in the repair shop. He remembered his project was to square a piece of bronze which he said to do with a file was all but impossible. But he kept at it on the side when he wasn't in class two days a week or working on the shop floor doing stuff for the journeymen or cleaning up. They worked 6 days a week and he made 30 marks a month. The apprenticeship lasted 3 1/2yrs. Because his father had a small shop with many machines and he was already familiar with all of them since he was 5yrs he was never forced to do the very basics.

In that shop they made sextants, the different gauges, thermometers, barometers, and compasses. He stayed there 7yrs in total then went into the aircraft industry making instruments for transports. From there he came to Canada, then the US doing aircraft instruments then ended up in the power generation industry and ended up working for PG&E at the local nuclear powerplant down the road from us. He is very humble about his abilities and makes incredible models of ships and RC aircraft. He also got into clock and watch repair.

Here's some of the apprentice/journeyman projects. The square was all made with files, a drill press and tap. The divider was filed too. Obviously the screw and knob were done with a lathe but notice the fit of the spring. It doesn't look soldered. The little vise is interesting in that it has a dovetail with gibs on the side. Notice too the dovetail is separate and dowel pinned and screwed into place. There is a clamp for clamping to a table. Notice the mortise joint which I think is silver soldered, but it's hard to tell. I know everything is a little rusty but they all have to be at least 60yrs old.

Attachments

- Joined

- Jan 2, 2019

- Messages

- 7,128

- Joined

- Feb 1, 2015

- Messages

- 9,948

My first mill was a round column mill. Over the years, it has been used for a vast multitude of work ranging from large to very small. The largest was facing a 100 lb. anvil and the smallest had features that were less than .01" in size. I have a 12" RT on the table and have on occasion set it up for vertical operation so I could do four axis machining.

The 5.3" quill travel can be challenging but with a little planning ahead and creative choice of tooling, it isn't a problem for virtually all work. I use collets to hold drills so the tool offset is comparable to the end mills. A tap wrench and tap used with a tap follower in most cases comes close to the drill length. For larger drills, moving off the work to mount a tool is conveniently accomplished by virtue of the DRO..

In those instances where it is necessary to move the head, it is useful to realize that the y axis reference changes very little. I would set up a reference edge in the x direction and re-reference to that edge after the move. Where it isn't necessary to maintain .001" accuracy, a dowel pin mating with a hole before and after the move is sufficient. If I had a piece of work mounted in my vise with the vise jaws parallel to the x axis, I would loosen the work and mate the pin to the hole and reclamp.

The 5.3" quill travel can be challenging but with a little planning ahead and creative choice of tooling, it isn't a problem for virtually all work. I use collets to hold drills so the tool offset is comparable to the end mills. A tap wrench and tap used with a tap follower in most cases comes close to the drill length. For larger drills, moving off the work to mount a tool is conveniently accomplished by virtue of the DRO..

In those instances where it is necessary to move the head, it is useful to realize that the y axis reference changes very little. I would set up a reference edge in the x direction and re-reference to that edge after the move. Where it isn't necessary to maintain .001" accuracy, a dowel pin mating with a hole before and after the move is sufficient. If I had a piece of work mounted in my vise with the vise jaws parallel to the x axis, I would loosen the work and mate the pin to the hole and reclamp.

I'm getting a round column mill too , but I'm still saving up so for now I have only a files and a small table clamp swivel Vise etc except for a hacksaw and I call it the portable machining center but I don't what I can make that is necessary for myselfMy first mill was a round column mill. Over the years, it has been used for a vast multitude of work ranging from large to very small. The largest was facing a 100 lb. anvil and the smallest had features that were less than .01" in size. I have a 12" RT on the table and have on occasion set it up for vertical operation so I could do four axis machining.

The 5.3" quill travel can be challenging but with a little planning ahead and creative choice of tooling, it isn't a problem for virtually all work. I use collets to hold drills so the tool offset is comparable to the end mills. A tap wrench and tap used with a tap follower in most cases comes close to the drill length. For larger drills, moving off the work to mount a tool is conveniently accomplished by virtue of the DRO..

In those instances where it is necessary to move the head, it is useful to realize that the y axis reference changes very little. I would set up a reference edge in the x direction and re-reference to that edge after the move. Where it isn't necessary to maintain .001" accuracy, a dowel pin mating with a hole before and after the move is sufficient. If I had a piece of work mounted in my vise with the vise jaws parallel to the x axis, I would loosen the work and mate the pin to the hole and reclamp.

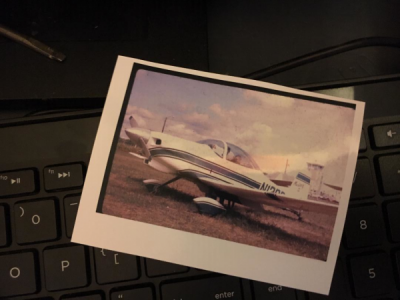

That is 匠 level.It was a Mustang II, a two seat performance plane. Unfortunately when my parents divorced he sold it just prior to certification. I did however get to enjoy many hours with him at the controls of a Cesna 152.

View attachment 296902

Cheers,

John

Sorry to hear your parents divorced.

Btw can you tell me how he build it.