So, I've been dreading this next step. It's stupid little round spacer to sandwich between the sprocket and inner bearing race.

Was dreading it mostly because I didn't have any scrap material around to do the job, and didn't want to use up a huge chunk of soild for a little 80x90x16mm ring.

Luckily, I had to stop by somewhere that had a chunk of 3" sch 20 pipe. Absolutely perfect! Had to bore just a bit out of the ID, and just skimmed to OD clean.

OK, so I did fight it. My HSS cutoff tools on this machine are always a problem! Ran back gear, nice and slow and about 3/4 way through it grabbed spun the spacer, and screwed everything up. Well, I sort of planned for this, the spacer was about .015" long. So, recovered by sawing off the extra, and taking it down to thickness on the surface grinder. It's also nice and parallel. So overall not as bad as I was imagining it to be.

Next is the clamp ring to clamp the sprocket, spacer, and bearing onto this square drive.

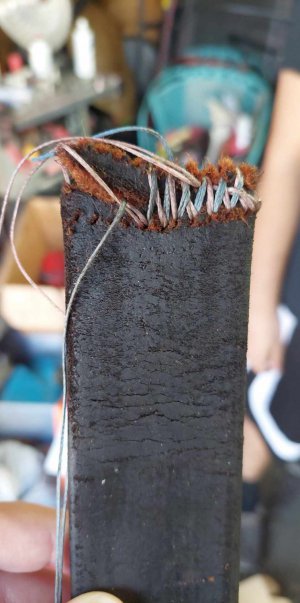

Edit: Probably not worth a new post. Buzzed out a chunk of HR, and set it up in the CNC mill. Made this little clamp. Feeling lazy, so let the surface grinder face off the one 'critical surface. Then assembled everything.

Next will be the hardware to support the outer race, and gearbox and hand wheel.