-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

- Joined

- Dec 20, 2021

- Messages

- 1,074

I think the bluing isn't that good in the threads, maybe due to residual oil, but overall, have to say I like this. Next time, I'll probably boil the parts in TSP first. I didn't' want to do that with our kitchen pots. Have to find a cheap pot somewhere.

I've had really good luck getting things clean with dish detergent in water in an ultrasonic cleaner. Like, get things to clean that stainless steel will rust type of clean. Even the low cost import ultrasonic cleaners are very good. $60 gets you a pretty nice machine...

Nifty trick, use a plastic bag to hold the part, water, and detergent. And fill your ultrasonic with water then add bag of parts to top it off. You waste less detergent for small parts, and save having to get soap out of the ultrasonic cleaner when done. I have a stack of polyethylene 'zip loc' bags, and run all sorts of solvents this way (acetone, paint thinner, alcohol, etc.)

- Joined

- Nov 25, 2015

- Messages

- 10,162

that's thinking outside the box. Very cool.. So the knurled piece is basically the taper of an er32 and presses up against the front of the collet?I made some ER32 collet blocks without the bulky nut to get in the way. They're also accurate on all sides within .0002".

View attachment 397148

pics of the construction or pieces?

I wish it was my idea but no. I was thinking it would be nice to make a block with the nut not being bigger than the block like most of them are. I saw a video on Stefan Gotteswinter's channel of a really nice collet block so I made a couple also.that's thinking outside the box. Very cool.. So the knurled piece is basically the taper of an er32 and presses up against the front of the collet?

pics of the construction or pieces?

So yes the front of the block has a 30° taper for the front and the knurled piece has the 8° taper on the inside. As the collet is tightened it butts up against the front of the block then it is forced to collapse inside the knurled part.

Found the video, starts at 18:55

- Joined

- Sep 2, 2013

- Messages

- 5,458

Have been back from the beach for two weeks now. Had two feet of snow to deal with, on both places. Got the water, and heat up and going, vehicles checked out. Had a pack rat in the shop, got him in a live trap and moved him five miles up the canyon. I think that thing sh*t on virtually everything in the building. My first project in the shop was to weld up some quick clamps I brought back from PR. They wouldn't fit in my suitcase, so I cut 3" off them, and presto chango, they fit in there just fine. Ground the ends, welded them up, and good as new. Mike

- Joined

- Nov 24, 2014

- Messages

- 3,749

@WobblyHand

Thanks for the detailed description of the process you used. I have one question, when you say "filtered warm water", please describe the filter you're referring to.

The T nuts look good from here.

Thanks for the detailed description of the process you used. I have one question, when you say "filtered warm water", please describe the filter you're referring to.

The T nuts look good from here.

- Joined

- Dec 18, 2019

- Messages

- 7,760

Activated charcoal filter - takes out chlorine and other stuff out of water. Use it for filtering water for drinking. Distilled water would work fine too.

We have an EverPure H104 filter for kitchen cooking and drinking.

We have an EverPure H104 filter for kitchen cooking and drinking.

- Joined

- Nov 14, 2016

- Messages

- 3,353

I've had really good luck getting things clean with dish detergent in water in an ultrasonic cleaner. Like, get things to clean that stainless steel will rust type of clean. Even the low cost import ultrasonic cleaners are very good. $60 gets you a pretty nice machine...

Nifty trick, use a plastic bag to hold the part, water, and detergent. And fill your ultrasonic with water then add bag of parts to top it off. You waste less detergent for small parts, and save having to get soap out of the ultrasonic cleaner when done. I have a stack of polyethylene 'zip loc' bags, and run all sorts of solvents this way (acetone, paint thinner, alcohol, etc.)

I've saved a bunch of small jelly jars, they work great for cleaning small parts in my ultrasonic cleaner.

Activated charcoal filter - takes out chlorine and other stuff out of water. Use it for filtering water for drinking. Distilled water would work fine too.

We have an EverPure H104 filter for kitchen cooking and drinking.

Great filter. Or did I already say that here?

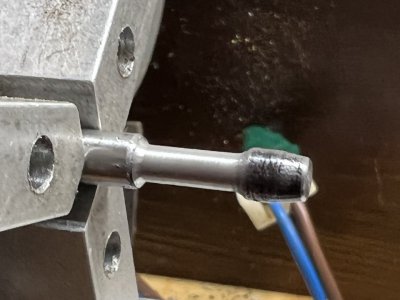

I’ve got a couple of 12v cordless Hitachi rotary tools that I really like because they are just so damned handy. No cord to plug in and just a well made rotary Dremel type tool. Unfortunately, since Hitach is now Metabo… they dropped this cordless rotary tool.

The problem I have is that the collets are hard to find. They are also different than Dremel collets.

So I have to make my own. I had planed to make hardened collets using O-1 tool steel. But after starting the project, I then realized that I’d probably screw the pup on the heat treatment process. I was afraid of warpage when cooling the heated steel on the dunking in oil.

So I figured I’d just leave it in its annealed state. FWIW, I made a collet using brass a while back. It worked okay for a while.

Since I have two units, I want one collet to be 1/8” and the other 3mm .

After forming the front I then drilled the hole using a 2.8mm drill bit and reamed using a 3mm reamer. I purchased both of those on EBay just for this project.

The problem I have is that the collets are hard to find. They are also different than Dremel collets.

So I have to make my own. I had planed to make hardened collets using O-1 tool steel. But after starting the project, I then realized that I’d probably screw the pup on the heat treatment process. I was afraid of warpage when cooling the heated steel on the dunking in oil.

So I figured I’d just leave it in its annealed state. FWIW, I made a collet using brass a while back. It worked okay for a while.

Since I have two units, I want one collet to be 1/8” and the other 3mm .

After forming the front I then drilled the hole using a 2.8mm drill bit and reamed using a 3mm reamer. I purchased both of those on EBay just for this project.

Attachments

-

DC221BB1-0D14-466A-85BC-5FD47A36E2CF.jpeg86.1 KB · Views: 42

DC221BB1-0D14-466A-85BC-5FD47A36E2CF.jpeg86.1 KB · Views: 42 -

1C697B85-E957-4DDD-B69A-8FACE8E59EA8.jpeg126.8 KB · Views: 42

1C697B85-E957-4DDD-B69A-8FACE8E59EA8.jpeg126.8 KB · Views: 42 -

9C547D1B-76C1-4E5C-9E89-D4F8FBFEEE4A.jpeg149.3 KB · Views: 36

9C547D1B-76C1-4E5C-9E89-D4F8FBFEEE4A.jpeg149.3 KB · Views: 36 -

AD272D21-46BF-4F99-9C0D-7F1AEC78B67A.jpeg75.6 KB · Views: 36

AD272D21-46BF-4F99-9C0D-7F1AEC78B67A.jpeg75.6 KB · Views: 36 -

DFEA10FE-4563-4A2A-B8D3-4D41A36CECCD.jpeg88.9 KB · Views: 36

DFEA10FE-4563-4A2A-B8D3-4D41A36CECCD.jpeg88.9 KB · Views: 36 -

76D2AC19-0CAD-4A41-A97C-CE4FCD06E23C.jpeg64.2 KB · Views: 38

76D2AC19-0CAD-4A41-A97C-CE4FCD06E23C.jpeg64.2 KB · Views: 38 -

CE5639FA-EAD9-48C2-A6BE-6A7FF93DC36E.jpeg101.7 KB · Views: 42

CE5639FA-EAD9-48C2-A6BE-6A7FF93DC36E.jpeg101.7 KB · Views: 42