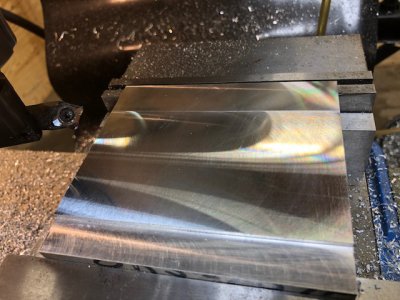

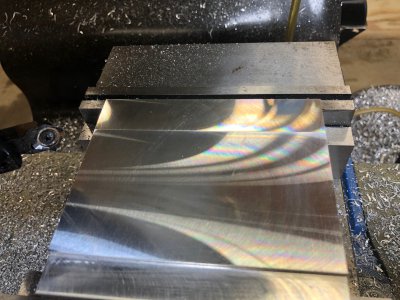

I'm still trying to learn feeds and speeds on this. I tried from about 600 RPMs to 1000 RPMs and feeds of 5 to 8 IPM. I want to try deeper cuts too. The deepest I tried was 0.005" So, what speeds, feeds, DOC, etc. would be appropriate for 1018 steel less than an inch wide?

Speeds are dependent on the material. Each material class will have a recommended cutting speed that is used to calculate RPM and the same calculation can be used to find a starting speed, whether you're turning or using a milling cutter like your fly cutter. There are tables for cutting speeds, given in SFM (surface feet per minute) all over the net and in reference texts.

LMS has a popular one.

Find the material you are working with and look up the cutting speed for the tool you're using. For 1018 being cut with a carbide tool, CS is about 800 sfm. Now plug that CS into the formula:

RPM = CS X 3.82 / Diameter, where CS is your cutting speed from the table, 3.82 is a constant and Diameter is the diameter of the cutter on the mill or the work piece on the lathe. In your case, the minimum diameter of your Superfly is 1.5" or so. Plugging in the values, RPM = 800 X 3.82 / 1.5 = 2,037 rpm. This same cut in aluminum would max out the speed of your mill.

Note also that as the extension of your tool increases, the diameter increases and the speeds will accordingly slow down a bit.

As we know, carbide needs speed so you'll be running pretty fast. Note also that these speeds you calculate are estimates or a starting point; they are not written in stone. Try that speed and go up or down as your results dictate. If you get chatter, slow down. If you need a better finish, speed up.

Feeds vary but carbide likes to cut a chip so don't dawdle with carbide. The tool should be constantly producing a chip. If the finish is too grainy, slow down.

Note that speeds and feeds vary with depth of cut. The deeper you go, the slower your speeds and feeds need to be. You need to play with it but the Superfly and the Sherline fly cutter can seriously hog material. You need to set a depth of cut and speed and then see how fast you can feed to get the results and finish you need. Over time, you will learn how to adjust to the cut, which is the mark of skill.

Hope this helps. If it is not clear, sing out.