- Joined

- Jan 24, 2015

- Messages

- 239

Next was making the two valve linkage bits. These are made from 3/16" brass hex stock. This part is just a little bit of turning, drilling and tapping for the valve connecting rod, and drilling for the retaining pin.

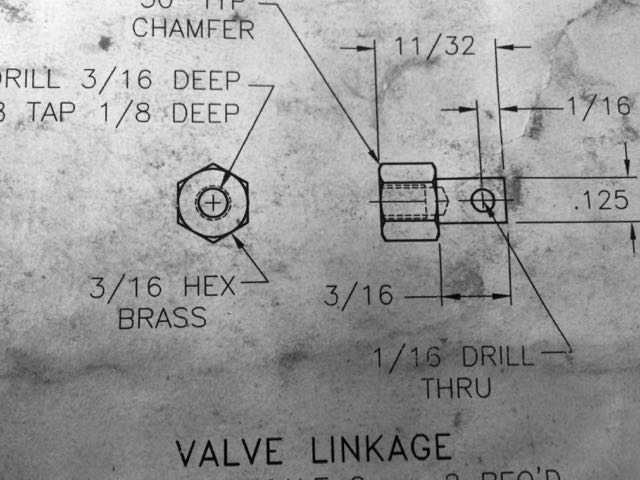

The plan for the valve linkage.

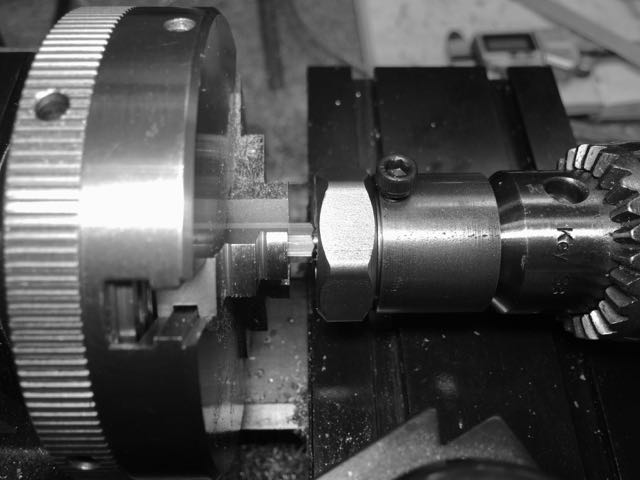

The linkage has been turned to the correct diameter for the correct distance, and is now being parted off.

The part was put back in the chuck and held by the turned portion. It was then drilled and tapped for the valve connecting rod.

The last machining step was to drill the cross hole for the keeper pin.

The valve linkage bits in a soft, romantic focus.

Next was making the two packing nuts. These are made from 1/4" hex stock. The stock is turned down to a .25 for the correct length. Then the clearance hole for the piston rod is drilled through. Then a hefty chamfer is placed on the end, and the turned portion is threaded with a die. Unfortunately, I did not have a very good die for this, so ended up using what is really a thread chasing chasing die. It worked fine, but is not ideal. The part is parted off, and the next one is made.

Packing nut raw stock and drawing.

Turning the stock down to .25 for the specified distance.

Chamfering the packing nut prior to threading.

The clearance passage for the piston rod was center drilled and then drilled through.

I ended up having to use a thread chasing die to thread the nuts. It worked, but was not ideal. Here the die is being held perpendicular to the part with one of my button die holders.

The finished packing nuts sitting in their respective gland retainers.

The last bits were 1) trimming the included copper pipe for the cross tube to the correct length and B) making a few pipe nipples for the steam/air plumbing.

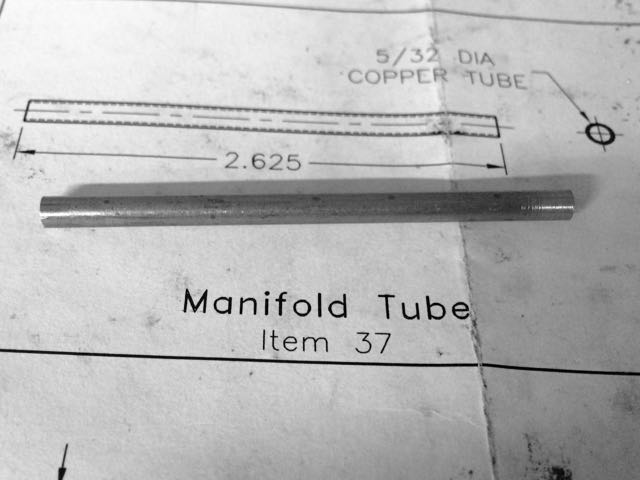

The manifold tube trimmed to the correct length via parting off in the lathe.

Various pipe nipples made for the steam/air plumbing. These are made from 3/16" model pipe and threaded 3/16-40 MP using a button die.

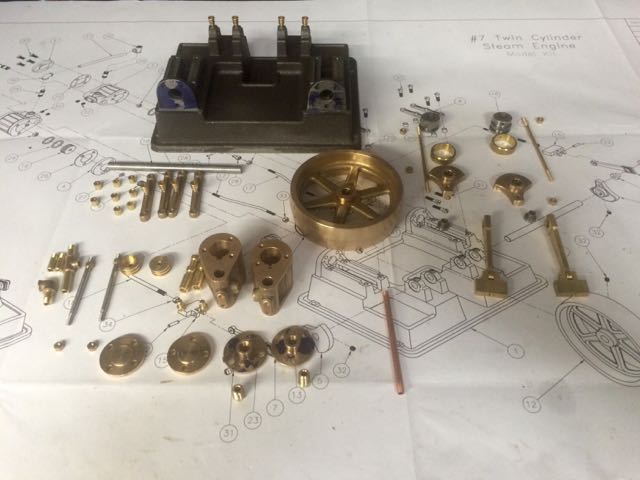

And after all this, spread across 16 posts, I ended with 61 machined pieces. Next up, assembly!

All the bits necessary to make a PMR #7 steam engine!

Cheers,

Tom

The plan for the valve linkage.

The linkage has been turned to the correct diameter for the correct distance, and is now being parted off.

The part was put back in the chuck and held by the turned portion. It was then drilled and tapped for the valve connecting rod.

The last machining step was to drill the cross hole for the keeper pin.

The valve linkage bits in a soft, romantic focus.

Next was making the two packing nuts. These are made from 1/4" hex stock. The stock is turned down to a .25 for the correct length. Then the clearance hole for the piston rod is drilled through. Then a hefty chamfer is placed on the end, and the turned portion is threaded with a die. Unfortunately, I did not have a very good die for this, so ended up using what is really a thread chasing chasing die. It worked fine, but is not ideal. The part is parted off, and the next one is made.

Packing nut raw stock and drawing.

Turning the stock down to .25 for the specified distance.

Chamfering the packing nut prior to threading.

The clearance passage for the piston rod was center drilled and then drilled through.

I ended up having to use a thread chasing die to thread the nuts. It worked, but was not ideal. Here the die is being held perpendicular to the part with one of my button die holders.

The finished packing nuts sitting in their respective gland retainers.

The last bits were 1) trimming the included copper pipe for the cross tube to the correct length and B) making a few pipe nipples for the steam/air plumbing.

The manifold tube trimmed to the correct length via parting off in the lathe.

Various pipe nipples made for the steam/air plumbing. These are made from 3/16" model pipe and threaded 3/16-40 MP using a button die.

And after all this, spread across 16 posts, I ended with 61 machined pieces. Next up, assembly!

All the bits necessary to make a PMR #7 steam engine!

Cheers,

Tom

Last edited: