-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM-1660TL

- Thread starter erikmannie

- Start date

Never assume That!I am turning between centers. I leveled the lathe as best as I can, and I hope that the ways are straight (i.e. not twisted).

For the time being, I am assuming that the tailstock offset was set correctly at the factory.

Make a 2 coller spool to setup your tail stock.

You need to get a great finish, a 6 inch long chunk is fine.

Face and center drill both ends then grip one end in Chuck and remove from center about 1/3 or so of OD leaving about 3/4 in chat each end.

Now place between centers and with carbide cutter that worked best for you with lathe as fast as it will go, take very light cuts.

Light cut is just enough to clean up your bad cut.

Light cuts removes need for dog, just crank TS tight.

Make ONE cut across both ends ad measure the od.

If different then move tail stock 1/2 the difference as needed (If larger towards front, smaller towards back)

Paint both ends with a Sharpie and take lighter cuts just until all ink is gone and re measure.

Repeat the movement of TS until both ends exactly the same.

Clean up the center when finished and polish both ends until looks good.

Repeat measurements after finish.

DONE!

TS now aligned, if it is a bit high or low the offset has corrected for it for now.

Place this spool in your tool box as you will use it often.

NEVER cut on it again, future uses you place center in tail stock, center in headstock or make one in Chuck then play spool in centers and dial indicator in tool post and adjust TS for same reading at both ends when carefully moving carriage.

Photo of one we made 20 years ago.

Sent from my SAMSUNG-SM-G930A using Tapatalk

- Joined

- Sep 8, 2019

- Messages

- 4,392

My main stable is Aloris inserts. I chose the ones for steel (A6, as I recall).

- Joined

- Dec 20, 2012

- Messages

- 9,422

Th

This arose out of my desire to level the lathe (in such a manner as to minimize twisting in the ways).

I got the machinist’s level pretty much dead on laying on the ways, as well as on the cross slide. That should establish a minimal twisting of the ways.

I was wondering how much of a taper I would cut with the ways as level (“normal”, hopefully) as I could get them.

Turning between centers is a good way to minimize taper, not reveal it. If you are trying to level the lathe, this is not the way to do it. Sorry.

If you have leveled the lathe with a spirit level then the next step, at least in my experience, would be to make sure the headstock is aligned with the ways. There are at least 4 ways to align the headstock that I've tried and there are probably more out there.

- Use a MT test bar in tthe spindle.

- Rollie's Dad's method

- Face a plate about 3" or more in diameter, then mount a dial indicator on the cross slide and check the run out in front and in back of the spindle centerline. Use the front as the reference and check behind the spindle; if the headstock is off, the DI will tell you exactly how much and in which direction to turn the headstock.

- Chuck a piece of 1-2" aluminum bar in a 3 jaw chuck with about 4-6" sticking out and without tailstock support. Use a very sharp HSS tool and take 0.010" off the OD to remove the skin, then take 0.003" to smooth it out and then take 0.001-0.002" and strive for a smooth finish. Measure the OD on the end and up near the chuck. Adjust the headstock until your cuts show an OD that is the same all the way down the bar. I use/prefer this method and it is very, very accurate. It is also self-proving in that it will show you exactly what the effects of moving the headstock does.

You should know that turning between centers is an accurate way to turn stuff but it lacks rigidity. Taking big cuts with a carbide tool can lead to chatter just because you're turning this way. Makes it difficult to sort out problems so I suggest you leave this method alone until the lathe is all set up, then play with it.

- Joined

- Jun 12, 2014

- Messages

- 5,058

This is a new machine, level the machine with a precision level and stop there. You will only mess things up if you start playing with bed twist to compensate for other errors that may be because of other factors. There is a specific method to checking head alignment, and as I indicated previously I have worked on several SunMaster lathes and they all have been dead on from the factory. I have yet to see a new lathe of reasonable quality that the bed was not ground correctly with the machine leveled. The tailstocks are often out of alignment from the factory and almost always need to be adjusted, and also might require slight refinements depending on the cutting situation. On the 1340GT and 1440GT I would say that about 1/2 the head alignment is off, and we are talking maybe 0.001" at 6". Take a look at this thread, same lathe manufacture and how he measured everything, it was dead on, so was my lathe and few other people I have assisted.

www.hobby-machinist.com

www.hobby-machinist.com

Also as Mikey suggested you should be holding the stock in the chuck, it will be much more rigid than between centers. Solid stock unsupported is somewhat material dependent as to stick out, rule of thumb is no more than 5 diameters. But it doesn't mean you can hold a 5" diameter piece of stock in the chuck with a 15" stick out. That gets loose and it could be an end game. After that the tailstock is used with a center and has more influence on if it cuts true. I would setup the level as per the factory with no bed twist, because you have a longer lathe, the last thing you want to do is twist the bed. The headstock alignment can also be influenced by jaw skew of the chuck, I would leave it all be until you get a bit more time on the lathe and maybe get someone to show you some more specifics if you feel there is alignment issue.

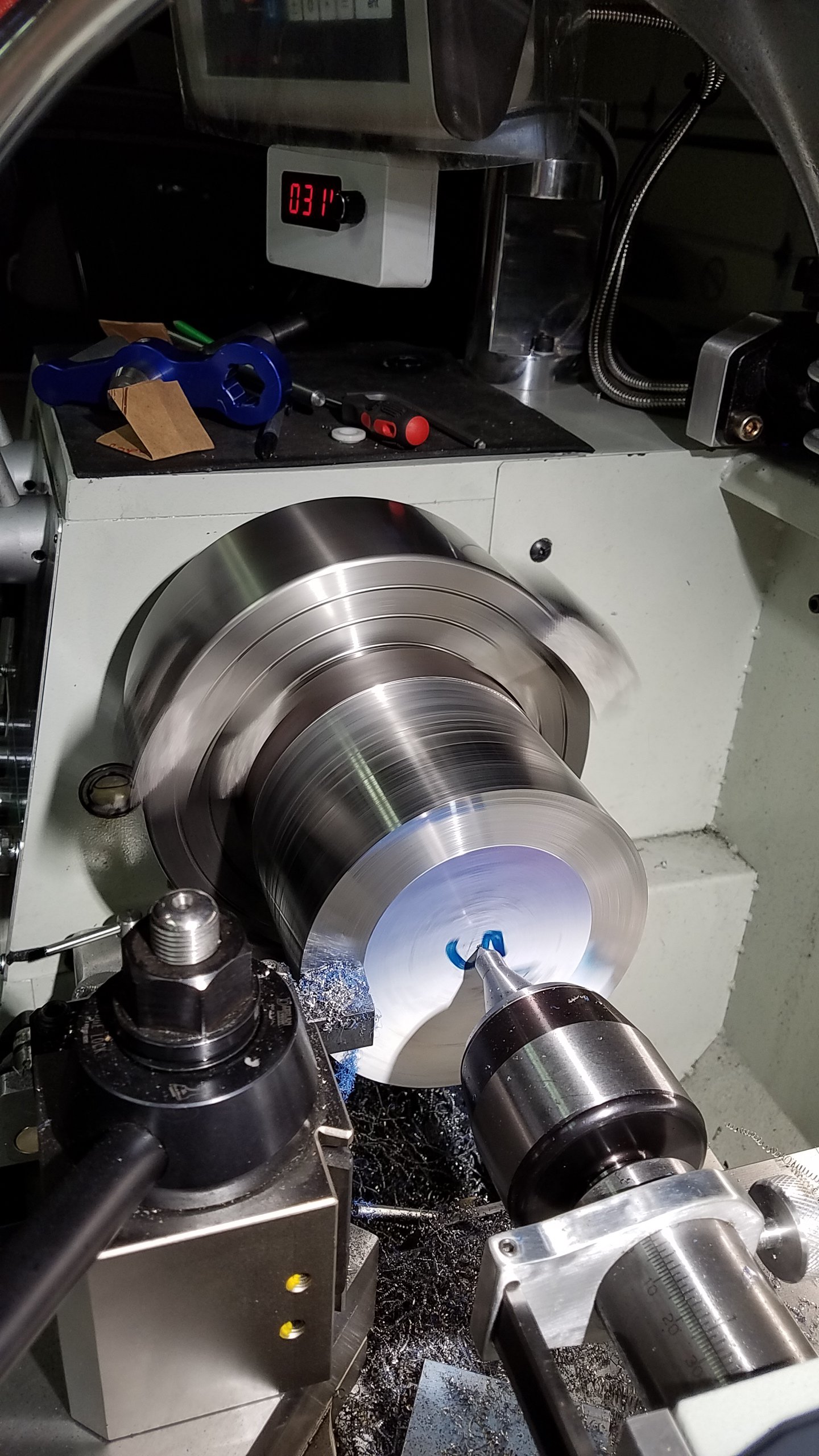

This is a 8620 steel 5" diameter x 6" long being turned down and is supported with a tailstock. Normally I prefer to use a heavier live center, but in this case I am facing almost to the center and then boring. There is not much holding the stock on the chuck end, I am roughing in the diameter and then facing at 550 SFM, 0.007 IPR and a DOC of around 0.050" with a Iscar carbide CCMT insert. You should be getting clean smooth turned surfaces. You also need to be carful when extended the jaws for larger work that they do not hit anything and also that there is enough teeth in the scroll that the jaw does not break free.

NEW ACRA 1640TE

That's a really nice machine, and the upgrades just put it over the top. Enjoy my friend. Mike

www.hobby-machinist.com

www.hobby-machinist.com

Also as Mikey suggested you should be holding the stock in the chuck, it will be much more rigid than between centers. Solid stock unsupported is somewhat material dependent as to stick out, rule of thumb is no more than 5 diameters. But it doesn't mean you can hold a 5" diameter piece of stock in the chuck with a 15" stick out. That gets loose and it could be an end game. After that the tailstock is used with a center and has more influence on if it cuts true. I would setup the level as per the factory with no bed twist, because you have a longer lathe, the last thing you want to do is twist the bed. The headstock alignment can also be influenced by jaw skew of the chuck, I would leave it all be until you get a bit more time on the lathe and maybe get someone to show you some more specifics if you feel there is alignment issue.

This is a 8620 steel 5" diameter x 6" long being turned down and is supported with a tailstock. Normally I prefer to use a heavier live center, but in this case I am facing almost to the center and then boring. There is not much holding the stock on the chuck end, I am roughing in the diameter and then facing at 550 SFM, 0.007 IPR and a DOC of around 0.050" with a Iscar carbide CCMT insert. You should be getting clean smooth turned surfaces. You also need to be carful when extended the jaws for larger work that they do not hit anything and also that there is enough teeth in the scroll that the jaw does not break free.

Last edited:

- Joined

- Sep 8, 2019

- Messages

- 4,392

Why are you using the ebay grinds vs the inserts ?

I am still getting used to this new machine. In school, we only used HSS. I just wanted to take it easy with low RPMs.

I am still getting used to the high RPMs needed for carbide. I need to work up to that. With a lathe dog in there, I didn’t want any drama today.

- Joined

- Sep 8, 2019

- Messages

- 4,392

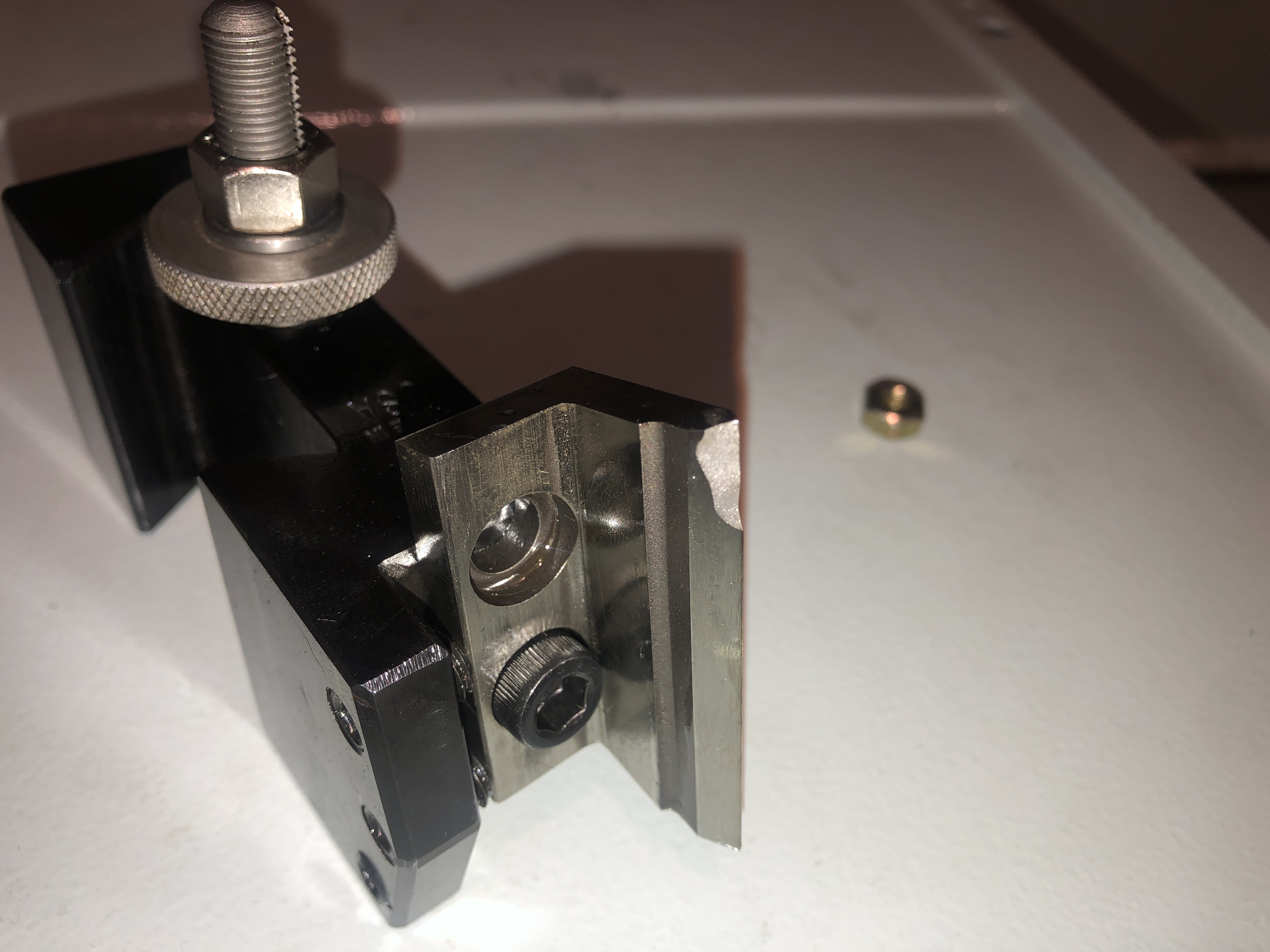

I tried a 1/4-20 thread tonight, and on the scratch pass I crashed the 60° HSS cutter into the work very near the chuck. The 60° form tool went past my safety groove (the length where I intended to disengage the half nut lever) and into the round stock that I had sticking out (which I never intended on getting into). This broke my HSS threading tool (see photo).

This happened because I somehow failed to disengage the half nut lever. I guess I wasn’t used to the feel of this particular lever.

Once the machine was turned off (I used the foot brake), the 60° tool was jammed against the chuck jaws, and I wasn’t able to disengage the half nut lever. I was a little concerned that I wouldn’t be able to get the machine going again because the half nut lever was stuck engaged and the form tool was very tight up against the chuck jaws.

The carriage was also flush up against my micrometer stop. I had to move that back out of the way and loosen the QCTP to make room to slide the tool holder back toward me.

Even then, I had to allow the still engaged half nut/leadscrew coupling to continue a little toward the headstock until I could disengage the half nut lever. This all makes the case for practicing the threading maneuvers out where there is room to do so.

This happened because I somehow failed to disengage the half nut lever. I guess I wasn’t used to the feel of this particular lever.

Once the machine was turned off (I used the foot brake), the 60° tool was jammed against the chuck jaws, and I wasn’t able to disengage the half nut lever. I was a little concerned that I wouldn’t be able to get the machine going again because the half nut lever was stuck engaged and the form tool was very tight up against the chuck jaws.

The carriage was also flush up against my micrometer stop. I had to move that back out of the way and loosen the QCTP to make room to slide the tool holder back toward me.

Even then, I had to allow the still engaged half nut/leadscrew coupling to continue a little toward the headstock until I could disengage the half nut lever. This all makes the case for practicing the threading maneuvers out where there is room to do so.

Last edited:

- Joined

- Sep 8, 2019

- Messages

- 4,392

I tried to recover by forming threads with the tool holder set up like this, but that definitely didn’t work. This set up must be for the chuck moving in reverse.