-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM 1440TL with Hitachi WJ200-075LF VFD Delivery, Clean up and VFD Set up

- Thread starter BladesIIB

- Start date

- Joined

- Dec 3, 2022

- Messages

- 8

I have the same lathe and vfd you do. What size wires did you use for the 24 volt control wiresMy PM 1440TL arrived on Friday and I spent the weekend getting the machine in place, cleaning off all the rust preventative and finishing all the VFD wiring. Took the whole weekend and I put together a video of the process from truck delivery, using a forklift and rollers to get it in place, all through clean up, and an overview of the wiring for the VFD. Check out the video on YouTube - 3 days of work in 35 minutes. Hope it will help someone with their planning process. I spent weeks planning for the deliver to ensure I had everything in place. Also spent about 3 weeks learning about the VFD an getting the enclosure side of it built and ready before the lathe arrived.

Last night I finally ran the break process and changed the oil in the Headstock and the Gearbox. Tomorrow I have the day off and will cut the block for the Quick Change Tool post I purchased and finish fitting the 4 jaw chuck and the Atlas collet chuck. Then it should be time to start making some parts. So far everything has gone really smooth. I was unsure about the VFD install, and Matt at PM told me there was a lot of support on this forum and he was correct. Huge shout out to Mark Jacobs mksj on this forum for all of his help and support getting me all set up with the VFD. There is a learning curve to get the VFD set up but in my opinion it was so worth it. Very glad I have a 3 phase machine and the added features the VFD provides.

Looking forward to learning and sharing on this forum. Currently working on a new lock mechanism for a folding knife. I have a couple of prototypes complete and am working through the patent process. May be a while before I can post those, but will share when I can.

View attachment 342274

- Joined

- Jun 12, 2014

- Messages

- 5,056

You can check the manual, I usually use 18, 20 or 22AWG. It only caries a few mA of current so the wire size is more for strength then capacity for the signal cables. You should terminate the VFD control wires with crimped ferrules that insert into the VFD terminals. If the wires are more than 3-4 feet, I use shielded cable, the ground shield is only temrinated at the VFD ground screw. Motor cable I use 12AWG, the specification is a minimum of 125% of the motor current rating (stock motor draws around 14A 3 phase). Motor cable if shielded needs to have the shield and ground terminated together at both ends of the cable, and be sure to insulate the shield mesh/wire. Use a high quality nylon insulated crimped terminals at both ends.

WJ200 VFD control wires 20AWG stranded wire

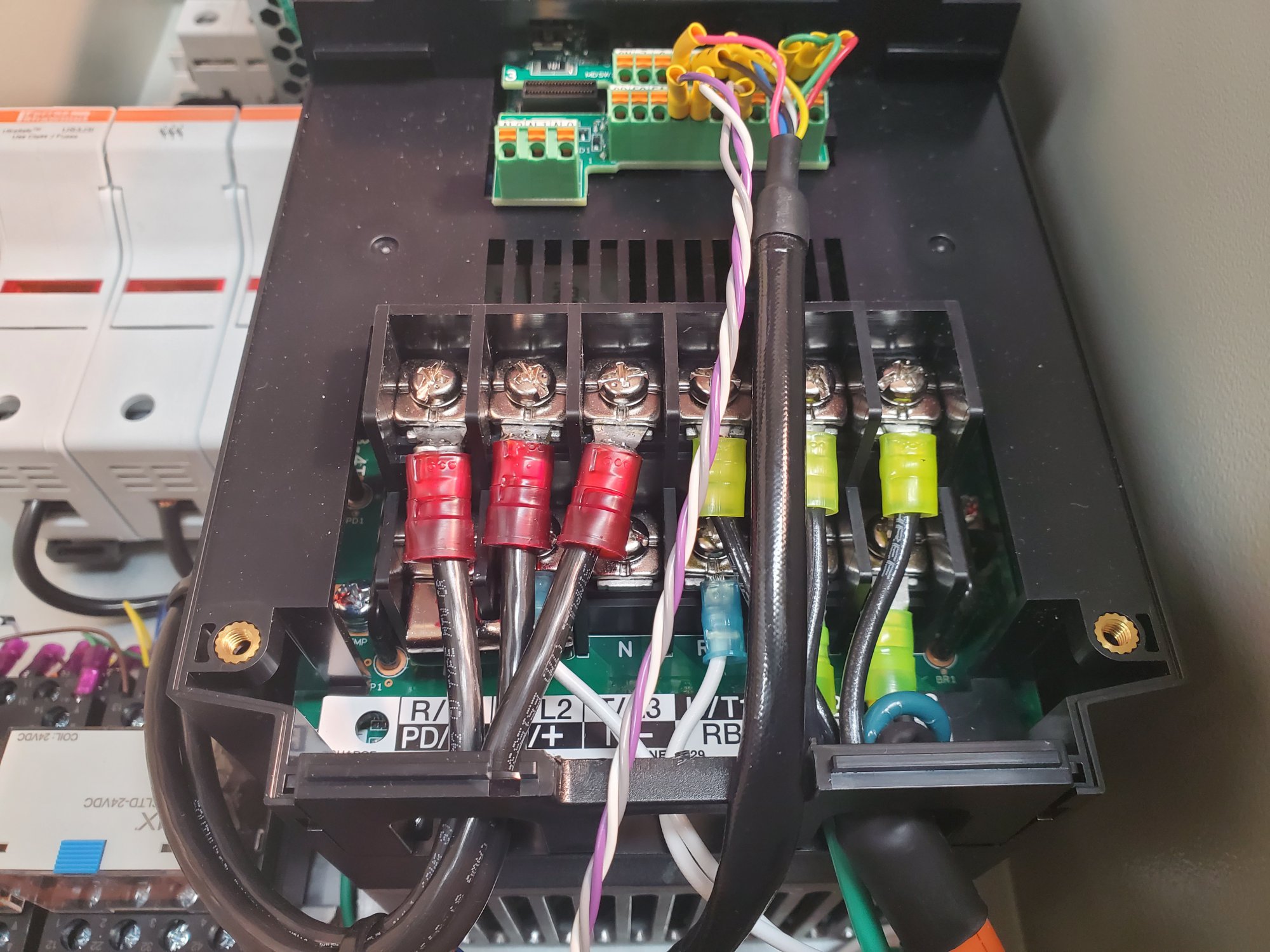

VFD Power and motor connections with ground

WJ200 VFD control wires 20AWG stranded wire

VFD Power and motor connections with ground

- Joined

- Dec 18, 2019

- Messages

- 7,333

I like the idea of using wire ferrules, good idea. Really don't like direct screw contact on stranded wire. Now off to find some. Also like those green connectors, what is the p/n or valid search term for them?You can check the manual, I usually use 18, 20 or 22AWG. It only caries a few mA of current so the wire size is more for strength then capacity for the signal cables. You should terminate the VFD control wires with crimped ferrules that insert into the VFD terminals. If the wires are more than 3-4 feet, I use shielded cable, the ground shield is only temrinated at the VFD ground screw. Motor cable I use 12AWG, the specification is a minimum of 125% of the motor current rating (stock motor draws around 14A 3 phase). Motor cable if shielded needs to have the shield and ground terminated together at both ends of the cable, and be sure to insulate the shield mesh/wire. Use a high quality nylon insulated crimped terminals at both ends.

WJ200 VFD control wires 20AWG stranded wire

View attachment 430031

VFD Power and motor connections with ground

View attachment 430032

- Joined

- Dec 3, 2022

- Messages

- 8

Thanks, this information will be very helpful.I like the idea of using wire ferrules, good idea. Really don't like direct screw contact on stranded wire. Now off to find some. Also like those green connectors, what is the p/n or valid search term for them?

- Joined

- Jun 12, 2014

- Messages

- 5,056

I crimp the ferrules, then use a label maker that has heat shrink tube cartridges. I had previously used a standard label maker tape but the labels always seemed to fall off over time. All my wiring is color coded, so one can always determine the connections.

You can buy the ferule crimper and ferrules through multiple sources. I usually buy the orange (22AWG) and white (20AWG) ferrules in bulk (German manufacturer) but that standard assortment kits are fine. I use locking fork terminals at the VFD terminals end, ring terminals for the motor connections as well as all grounds. Either double shell crimps, or 3M heat shrink type. You do not want to use vinyl insulated terminals, nylon/heat shrink style is much better. You need to use a decent quality terminal crimper, with specific anvils for the type of terminal you are using.

HSC8 6-6A Hexagon Crimper

Nylon insulated double crimps copper alloy, the steel/vinyl types are crap in my experience.

3M, T&B (Sta-Kon) RC10-10FL,12-10 AWG Nylon Locking Fork Terminal #10

3M®, Molex, T&B - 12-10 AWG #10 Stud Nylon Insulated w/ Grip Ring Terminal

3M®, Molex, T&B - 12-10 AWG #10 Stud Nylon Insulated w/ Grip Ring Terminal

FYI, the input power wire size to the VFD must be at least 125% of the rated input of the VFD, regardless of what the output amps is set to and/or using it in a derated mode. The WJ200-075LF specifies #6 wire on the input power connections. With fusing or a breaker, there is also a difference in the sizing amperage rating/type if you use a DC buss choke. With this size VFD (WJ200) with single phase input driving a 5Hp motor, I usually do not use a DC choke, but it depends on the VFD manufacturer and what they specify with the appropriate deratings.

You can buy the ferule crimper and ferrules through multiple sources. I usually buy the orange (22AWG) and white (20AWG) ferrules in bulk (German manufacturer) but that standard assortment kits are fine. I use locking fork terminals at the VFD terminals end, ring terminals for the motor connections as well as all grounds. Either double shell crimps, or 3M heat shrink type. You do not want to use vinyl insulated terminals, nylon/heat shrink style is much better. You need to use a decent quality terminal crimper, with specific anvils for the type of terminal you are using.

HSC8 6-6A Hexagon Crimper

https://www.amazon.com/IWISS-Self-adjusting-Hexagonal-AWG23-10-End-sleeves/dp/B00H950AK4/ref=sr_1_47

Nylon insulated double crimps copper alloy, the steel/vinyl types are crap in my experience.

3M, T&B (Sta-Kon) RC10-10FL,12-10 AWG Nylon Locking Fork Terminal #10

Thomas&Betts(Sta-Kon) RC10-10FL,12-10 AWG Nylon Locking Fork Terminal #10 QTY:50 786210887531 | eBay

; Copper; Tin; Nylon. New, pictures are of the actual item. Wire Size : 12-10 AWG. Insulation Material : Nylon. Insulation Type : Nylon. Connector Type : Fork. Shape : Fork. Type : Fork Tongue.

www.ebay.com

3M MH10-14FLK Locking Fork Terminal Heat Shrink 12-10 Yellow 1/4" Stud 10-Pack | eBay

3M MH10-14Yellow Heat Shrink Insulation. Marine quality. This item fits 1/4" studs. Listed below is a chart that you can use as a guideline. This chart is to be used as a guideline only. We do not take responsibility for any information provided.

www.ebay.com

13-10-NB Nylon w/Insulation Grip Ring Terminals Yellow 12-10 AWG #10 Stud 100EA | eBay

The nylon insulation provides relief from vibration that can cause the wire to fail prematurely. WARNING: This product can expose you to chemicals including lead, which is known to the State of California to cause cancer.

www.ebay.com

Molex 19073-0113 12-14 AWG Ring Terminal Nylon Insulated Yellow #10 Stud 10 Pack 7447139938904 | eBay

Yellow Nylon Insulation. Marine quality. This item fits #10 studs. Not the exact size you will be receiving. Listed below is a chart that you can use as a guideline. This chart is to be used as a guideline only.

www.ebay.com

FYI, the input power wire size to the VFD must be at least 125% of the rated input of the VFD, regardless of what the output amps is set to and/or using it in a derated mode. The WJ200-075LF specifies #6 wire on the input power connections. With fusing or a breaker, there is also a difference in the sizing amperage rating/type if you use a DC buss choke. With this size VFD (WJ200) with single phase input driving a 5Hp motor, I usually do not use a DC choke, but it depends on the VFD manufacturer and what they specify with the appropriate deratings.

Hi @BladesIIB

Nice install and video! Thanks for sharing. I am always surprised that folks do not put the RPM display in the front panel. It will fit just fine and reduces the wire clutter. I managed to put a lot of displays (RPM, Revolution count, potentiometer meter) in my PM1440GT front panel but it required creative spacing. Here are a couple of pictures:

From a safety stand point having your Power On-Off switch on the wall behind and above the lathe would be a concern for anyone shorter than you are. One basically has his belly hanging over the lathe when the power is being turned on to the VFD etc. You could put a switch for this off to the side of the lathe.

WRT to patents. I have a number of them and I have yet to see one that gets awarded that did not cost at least $10k plus the "maintenance" fees. One of mine I also filed in Japan and Korea and just the translation fees were over $25k. You certainly want to file as a "small entity" (person or business) to try to lower the costs of the maintenance fees. Most of my patents cost a lot more than this. This is only the beginning. The real cost is incurred when you try to enforce them against a big company! Their are a number of "tricks" in patent filing and if you want to talk about it you can message me. I am not a lawyer, but I have a lot of experience... .both good and bad. You can file a provisional application for a couple hundred dollars which will get you protection for a year and allows you to make a disclosure... while to finish up your concepts, get things in order, and get help/financing in preparing the final application. You can write one specification, but file for multiple patents.... which seems to be a good thing to have done when it comes to enforcement. You can file things called continuation patents, divisional patents, etc. but there are timing requirements for this. By the way, most patents are pretty much worthless, so be sure to do a really good job of finding all of the prior art (patents, products, literature both US and foreign) before you file and include all that you can as references. Pointing out how your invention solves the problems of other prior art, especially prior art that is really close to your invention, helps make your patent much stronger.

Good luck,

Dave L.

Nice install and video! Thanks for sharing. I am always surprised that folks do not put the RPM display in the front panel. It will fit just fine and reduces the wire clutter. I managed to put a lot of displays (RPM, Revolution count, potentiometer meter) in my PM1440GT front panel but it required creative spacing. Here are a couple of pictures:

picture

adding a counter to my VFD converted PM1440GT

From a safety stand point having your Power On-Off switch on the wall behind and above the lathe would be a concern for anyone shorter than you are. One basically has his belly hanging over the lathe when the power is being turned on to the VFD etc. You could put a switch for this off to the side of the lathe.

WRT to patents. I have a number of them and I have yet to see one that gets awarded that did not cost at least $10k plus the "maintenance" fees. One of mine I also filed in Japan and Korea and just the translation fees were over $25k. You certainly want to file as a "small entity" (person or business) to try to lower the costs of the maintenance fees. Most of my patents cost a lot more than this. This is only the beginning. The real cost is incurred when you try to enforce them against a big company! Their are a number of "tricks" in patent filing and if you want to talk about it you can message me. I am not a lawyer, but I have a lot of experience... .both good and bad. You can file a provisional application for a couple hundred dollars which will get you protection for a year and allows you to make a disclosure... while to finish up your concepts, get things in order, and get help/financing in preparing the final application. You can write one specification, but file for multiple patents.... which seems to be a good thing to have done when it comes to enforcement. You can file things called continuation patents, divisional patents, etc. but there are timing requirements for this. By the way, most patents are pretty much worthless, so be sure to do a really good job of finding all of the prior art (patents, products, literature both US and foreign) before you file and include all that you can as references. Pointing out how your invention solves the problems of other prior art, especially prior art that is really close to your invention, helps make your patent much stronger.

Good luck,

Dave L.

- Joined

- Jul 29, 2014

- Messages

- 2,844

I too have some experience in the patent field…I hold 5 in energy and have assigned a number more in computer storage and internet devices. For those of us hobby machinists, it’s extremely unlikely that anything we think of has not been covered by prior art, most likely by Perfessor Von Fustenberg in 1825 or so. It’s unlikely you could sell to a big company…most are very wary of unsolicited proposals and if they were to talk to you would probably have you sign that they are not constrained in any way and may have thought of this themselves in any event. Every other path has big expensive pitfalls, so be careful.

- Joined

- Sep 1, 2020

- Messages

- 554

Apologies for the delay. Looks like @mksj gave you the info. He helped me select wire as well. I used an 18gauge 8 strand for mine. Here is a link to what I purchased.I have the same lathe and vfd you do. What size wires did you use for the 24 volt control wires