-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM 1440TL with Hitachi WJ200-075LF VFD Delivery, Clean up and VFD Set up

- Thread starter BladesIIB

- Start date

- Joined

- Sep 8, 2019

- Messages

- 4,392

I just received a PM-1660TL two weeks ago. I am certain that our machines made the trip over from Taiwan together.

I enjoyed watching your video. Have fun with your new machine!

I enjoyed watching your video. Have fun with your new machine!

Last edited:

- Joined

- Sep 1, 2020

- Messages

- 554

Thank you, glad you liked the video. Enjoy that 1660 as well. I am sure you are right they traveled over together.I just received a PM-1660TL two weeks ago. I am certain that our machines made the trip over from Taiwan together.

I enjoyed watching your video. Have fun with your new machine!

- Joined

- Mar 2, 2021

- Messages

- 84

Awesome! One thing I'm confused about is the VFD. Doesn't the wj200-075lf require three phase power on the input? Are you feeding it 3-phase power from the wall, or is it possible to wire the wj200-075lf with single phase 200V on the input side?My PM 1440TL arrived on Friday and I spent the weekend getting the machine in place, cleaning off all the rust preventative and finishing all the VFD wiring. Took the whole weekend and I put together a video of the process from truck delivery, using a forklift and rollers to get it in place, all through clean up, and an overview of the wiring for the VFD. Check out the video on YouTube - 3 days of work in 35 minutes. Hope it will help someone with their planning process. I spent weeks planning for the deliver to ensure I had everything in place. Also spent about 3 weeks learning about the VFD an getting the enclosure side of it built and ready before the lathe arrived.

Last night I finally ran the break process and changed the oil in the Headstock and the Gearbox. Tomorrow I have the day off and will cut the block for the Quick Change Tool post I purchased and finish fitting the 4 jaw chuck and the Atlas collet chuck. Then it should be time to start making some parts. So far everything has gone really smooth. I was unsure about the VFD install, and Matt at PM told me there was a lot of support on this forum and he was correct. Huge shout out to Mark Jacobs mksj on this forum for all of his help and support getting me all set up with the VFD. There is a learning curve to get the VFD set up but in my opinion it was so worth it. Very glad I have a 3 phase machine and the added features the VFD provides.

Looking forward to learning and sharing on this forum. Currently working on a new lock mechanism for a folding knife. I have a couple of prototypes complete and am working through the patent process. May be a while before I can post those, but will share when I can.

View attachment 342274

- Joined

- Sep 1, 2020

- Messages

- 554

Jeremy, it is possible to wire it with Single Phase Input, so yes I have single phase 220V going n from the wall. The draw etc. is still based on the full power of the VFD even though I am using half for my motor. That part gets beyond my expertise for sure. I did put together a full video on just the VFD though that provides a lot more detail. Link below.

- Joined

- Mar 2, 2021

- Messages

- 84

Awesome, thank you! I *just* ordered a 1440TL, but was also considering the 1440GT. I'm not a gunsmith so the shorter spindle was not a particularly big draw for me and my final choice was in no small part from watching your YouTube channel, so thank you, thank you!

How did you learn that you could connect only the two single phase inputs to the VFD (ignoring the third leg on the input)? Obviously you have it installed and working, so not questioning your success with it, but struggling to find anything in the manual (online) that describes that kind of a setup with the w200-075lf.

Thanks again for your help, and for sharing your experience here and on YouTube!

How did you learn that you could connect only the two single phase inputs to the VFD (ignoring the third leg on the input)? Obviously you have it installed and working, so not questioning your success with it, but struggling to find anything in the manual (online) that describes that kind of a setup with the w200-075lf.

Thanks again for your help, and for sharing your experience here and on YouTube!

- Joined

- Sep 1, 2020

- Messages

- 554

Appreciate the feedback on the videos and glad they helped you make your decision. I was similar on the GT. Not a gunsmith either and really like the ability to cut metric and standard threads with no change gears so big plus on the TL. I relied on the expertise of PM who sold me the VFD and said it was sized right. I believe I did find somewhere on the Hitachi site in their FAQ’s about it. And of course mksj on this forum was a huge help getting it all put together. It clearly does work well so can’t question their knowledge.

- Joined

- Mar 2, 2021

- Messages

- 84

Cool, based on that tip, I found this document on Hitachi's website, for anyone else curious about the topic:

- Joined

- Jun 12, 2014

- Messages

- 5,056

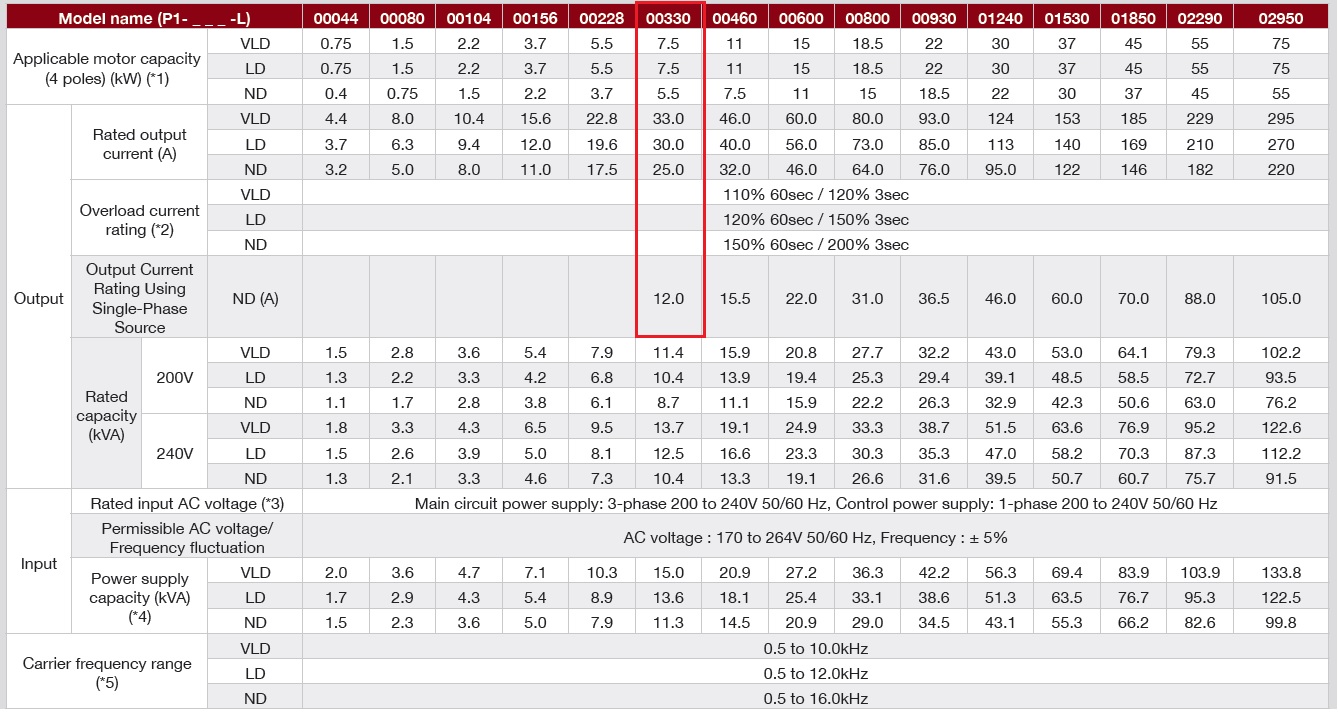

Some VFD manufactures will specify the 2 terminals if used for single phase use of a 3 phase input VFD, others like Hitachi specify it in a separate document. In many VFD's either L2 or L3 can be used for the other leg, as they all connect to the input diodes which rectify the AC. In some VFD's the fans run off of the AC from 2 phases, so it is important to check the documents or email technical. The other factor is to understand the VFD load type and the derating for single phase. The general convention is a derating of 1.7 for single phase input for a 3 phase input VFD, but the range can vary widely. Example is Hitachi's new line (SF-P1) of VFD's, if you look at say their SJ – P1-00330-LFUF which is listed as a 7.5Hp model 200-240 volt, 3 phase, 33/30/25A depending on the load type, it is only rated for 12A with single phase input so 3 Hp motor. The WJ200 is an older model, but is a bit more rugged and has less derating, Other VFD's like the new models from Automation Direct the derating is a factor of 3.

With the 5 Hp motor, one can use either the Hitachi WJ200-055LF (25A) or WJ200-075LF (33A) with a derating of 1.7 quoted for this model. The price difference is small between these two so it pays to go with the WJ200-075LF. The newer Hitachi VFD whihch is the SF-P1 series one would need to go with their 10 Hp (46A) P1-00460-LFUF which is rated 15.5A derated for single phase which is about the same as the WJ200-055LF. Price of the WJ200-055LF is around $560, WJ200-075LF is around $680 and the P1-00460-LFUF around $725. Using a DC choke can help reduce the input current and fusing requirements, and on some VFD's like the Yaskawa the derating is only valid when used with a DC buss choke. There are a number of different variables to consider and one needs to go off of your motor amps and the VFD output amps for the specific operating conditions. Yaskawa is also one of the few VFD manufactures that offers a native single phase input 5 Hp model (CIMR-VUBA0018FAA), but have also used their 3 phase input (10Hp, 40A) CIMR-VU2A0040FAA derated for this size motor/lathe. I used both with installs on this size lathe.

www.driveswarehouse.com

www.driveswarehouse.com

www.driveswarehouse.com

www.driveswarehouse.com

With the 5 Hp motor, one can use either the Hitachi WJ200-055LF (25A) or WJ200-075LF (33A) with a derating of 1.7 quoted for this model. The price difference is small between these two so it pays to go with the WJ200-075LF. The newer Hitachi VFD whihch is the SF-P1 series one would need to go with their 10 Hp (46A) P1-00460-LFUF which is rated 15.5A derated for single phase which is about the same as the WJ200-055LF. Price of the WJ200-055LF is around $560, WJ200-075LF is around $680 and the P1-00460-LFUF around $725. Using a DC choke can help reduce the input current and fusing requirements, and on some VFD's like the Yaskawa the derating is only valid when used with a DC buss choke. There are a number of different variables to consider and one needs to go off of your motor amps and the VFD output amps for the specific operating conditions. Yaskawa is also one of the few VFD manufactures that offers a native single phase input 5 Hp model (CIMR-VUBA0018FAA), but have also used their 3 phase input (10Hp, 40A) CIMR-VU2A0040FAA derated for this size motor/lathe. I used both with installs on this size lathe.

WJ200-055LF

WJ200-075LF