- Joined

- Aug 22, 2012

- Messages

- 4,295

In my never ceasing search for more rigidity in my lathe I decided to make a plinth for the qctp.

In its normal configuration I can often see the complete top slide assembly flex slightly. (I think I punish my lathe a bit)

After seeing Bill G's plinth I felt it was time to go.

I forgot to take pics as I started but the base was a chunk of mild steel hot rolled plate 19 mm thick.

I faced all sides in the 4 jaw and I must say that facing the sides jutting that far out of the 4 jaw was a bit wild.

The centre hole was drilled and tapped for 14 x 1.25 mm.

The hole in the qctp is 14.7 mm dia so I turned the centre post down to 14.68 mm, it slides on firmly but smoothly.

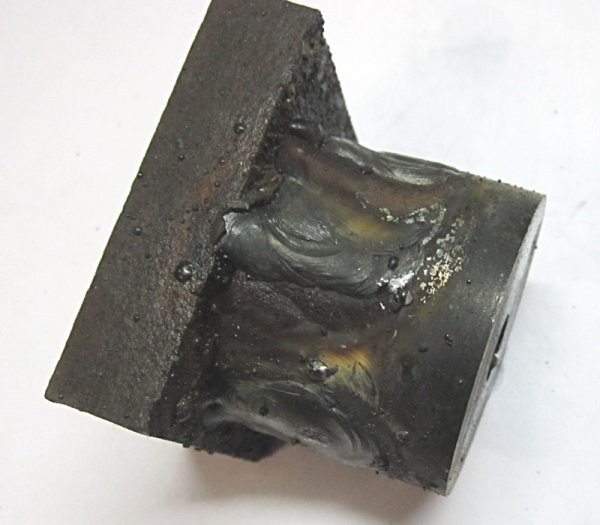

I needed more height so the central boss is 19mm x 57mm dia. Its bored to 14.68 so the post is pulled down into the hole for a very very tight fit. Then I welded the boss to the base plate.

I made it round so the tool post holders can sit down lower, this allows 1/2" tool bits a bit more height adjustment.

I took a skim from the middle of the base plate to ensure it sat dead flat on the cross slide.

I also took a light skim from the top of the plate to remove all the weld spatter.

Now I needed a lump of 50mm dia bar and there was none available so I turned a taper into 2 chunks of 19mm plate

and welded them together

and then turned and tapped for the 14mm post with a 10x1mm hole for the handle.

All in place but waiting for balls for the handles.

I hope to try it out tomorow.

The handle isnt horizontal as it looks in the photo but tilted upwards the same angle as the taper on the top nut.

In its normal configuration I can often see the complete top slide assembly flex slightly. (I think I punish my lathe a bit)

After seeing Bill G's plinth I felt it was time to go.

I forgot to take pics as I started but the base was a chunk of mild steel hot rolled plate 19 mm thick.

I faced all sides in the 4 jaw and I must say that facing the sides jutting that far out of the 4 jaw was a bit wild.

The centre hole was drilled and tapped for 14 x 1.25 mm.

The hole in the qctp is 14.7 mm dia so I turned the centre post down to 14.68 mm, it slides on firmly but smoothly.

I needed more height so the central boss is 19mm x 57mm dia. Its bored to 14.68 so the post is pulled down into the hole for a very very tight fit. Then I welded the boss to the base plate.

I made it round so the tool post holders can sit down lower, this allows 1/2" tool bits a bit more height adjustment.

I took a skim from the middle of the base plate to ensure it sat dead flat on the cross slide.

I also took a light skim from the top of the plate to remove all the weld spatter.

Now I needed a lump of 50mm dia bar and there was none available so I turned a taper into 2 chunks of 19mm plate

and welded them together

and then turned and tapped for the 14mm post with a 10x1mm hole for the handle.

All in place but waiting for balls for the handles.

I hope to try it out tomorow.

The handle isnt horizontal as it looks in the photo but tilted upwards the same angle as the taper on the top nut.