Plenty of eye candy today...

Well, it seems CME wasted no time shipping this. It arrived much faster than I imagined possible...

So far... It's impressive. I've been inside quite a few chucks and this is really quite a surprise. It has not been spun on the machine yet but will in a day or two.

It arrived as two items, the backplate and chuck. They are not pre-fitted and, in my opinion, it's not reasonable to expect they would be. BTW, the proof shaft on the table is one I made a few years ago. It's 1" diameter, 1045, TGP and varies no more than +/- 0.0003 over 2 feet. I'll check the chuck with this when the time comes. Unfortunately, I do not have a proof shaft of say 2 or 3" diameter but, there are other tricks up my sleeve.

Anyhow, the chuck came packed in heavy cosmoline-like shipping oil. Anytime you get something packed in grease, it's a sign it should be somewhat disassembled (or at least flushed-out) and lubed properly. As it arrived, it's stiff to spin with the wrench but, I would expect that given it's still in the packing oil and needs to be flushed out.

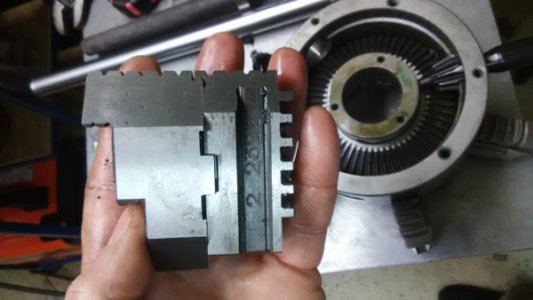

Here's a few more pics of the guts. Everything looks fine (once you get past the smell of gritty cosmoline) and is a very nice design. I did a quick nondestructive hardness test (LEEB type) and just as I thought, it's hard... -really hard... RC 62.

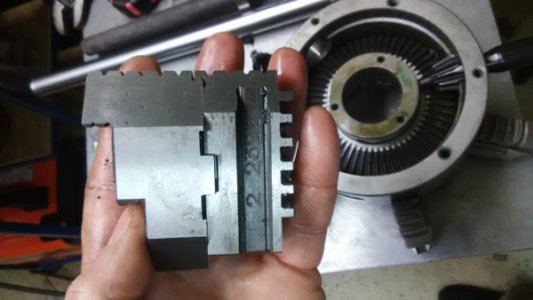

The Jaws are very uniform and they took the time to number and serialize them. There are burrs on some areas but, I've seen a lot worse. All of them weighed 437 grams -exactly.

Every possible dimension was measured and compared to the same dimension of a different jaw slot. Amazing... Basically, dead-on everywhere I checked with no variances greater than 1 thou -anywhere. The machining is bright and clear in all the areas where bright and clear machining is needed. The thickness of the spiral thread was measured in about a dozen places. -Dead-on everywhere. I do not have a means to measure the the spiral itself however. The proof will be in the pudding.

And best of all, the wrench is decent quality too (no idiot spring on there).

Pleasantly surprised so far. I'm going to deburr a few areas, flush this thing out and get some proper lube in there, slap the back on (as-is) and give it a spin soon. I'll check it on a static balancer beforehand as a measure of caution. I've mounted and tuned a couple dozen chucks and never had a generic backplate that didn't need some tweaking so, there's no doubt this will come apart again for fine tuning. Also, I will probably do a more detailed job of deburring the second time around and am also thinking of converting this to a set-tru type chuck. At quick glance, it should be possible.

Ray