- Joined

- Dec 26, 2015

- Messages

- 3

Hi Tim

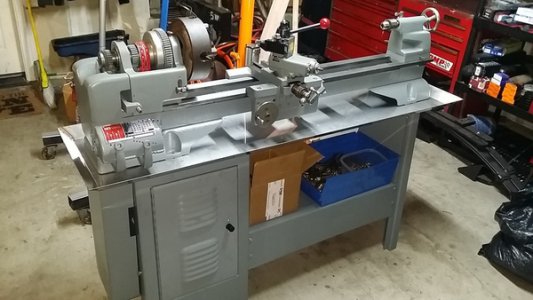

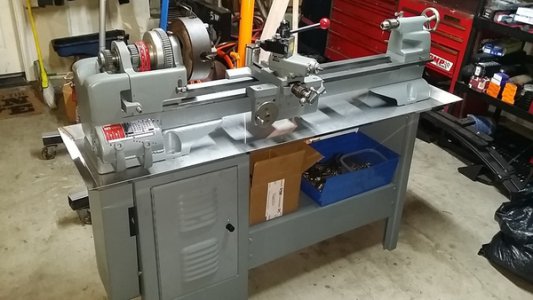

I bought the exact same machine about a year ago. I had the seller do some demos to determine general condition and it functioned quite well with minor signs of wear. Once at home I began cleaning everything I could readily access. In the process I discovered old swarf and grit on the gears. At this point I decided to go completely through it. I completely disassembled, inspected and cleaned every piece. It is quite a project but I'm glad I decided to do it before beginning general operations. I found several things that needed attention. I replaced the bushings on the intermediate motor drive shaft. A loose pulley on the motor shaft had damaged the shaft. I tore down the (original) motor which was otherwise in good condition. I was able to salvage the shaft by filing out the keyway and knocking off ridges caused by the loose pulley set screw. The pulley being softer was damaged beyond repair. I found another online as well as a couple of gears in better condition than mine. I discovered a couple of loosening set screwsI replaced all the belts with the now available link type which also allows replacement of the belts without breaking down the head stock assembly which was a real SOB. I am now in the process of reassembly. Lubing and installing the various parts is quite rewarding knowing how necessary it needed to be done. It's going to be a sweet machine when completed.

The machine came with a good assortment of collets but no puller. I found steady rests, a fixed center, a milling attachment (Clausing) and all the original tool holders even though I have the same quick change post as you. Over time I will acquire more pieces as they become necessary during use. This lathe is my baby. I'm a new member too. I will post pictures after my initial posts.

I bought the exact same machine about a year ago. I had the seller do some demos to determine general condition and it functioned quite well with minor signs of wear. Once at home I began cleaning everything I could readily access. In the process I discovered old swarf and grit on the gears. At this point I decided to go completely through it. I completely disassembled, inspected and cleaned every piece. It is quite a project but I'm glad I decided to do it before beginning general operations. I found several things that needed attention. I replaced the bushings on the intermediate motor drive shaft. A loose pulley on the motor shaft had damaged the shaft. I tore down the (original) motor which was otherwise in good condition. I was able to salvage the shaft by filing out the keyway and knocking off ridges caused by the loose pulley set screw. The pulley being softer was damaged beyond repair. I found another online as well as a couple of gears in better condition than mine. I discovered a couple of loosening set screwsI replaced all the belts with the now available link type which also allows replacement of the belts without breaking down the head stock assembly which was a real SOB. I am now in the process of reassembly. Lubing and installing the various parts is quite rewarding knowing how necessary it needed to be done. It's going to be a sweet machine when completed.

The machine came with a good assortment of collets but no puller. I found steady rests, a fixed center, a milling attachment (Clausing) and all the original tool holders even though I have the same quick change post as you. Over time I will acquire more pieces as they become necessary during use. This lathe is my baby. I'm a new member too. I will post pictures after my initial posts.